WQS energy-saving double suction submersible sewage pump

Number of views:11

QR code:

Add time:2025-04-09

Brief:

WQS energy-saving double suction submersible sewage pump is a new type of pump and product developed by our company according to market demand. The pump solves the problem that the axial tension of the single-suction submersible pump is large and the mechanical seal is easy to leak in the case of higher head.

【 Product Overview 】

WQS energy-saving double suction submersible sewage pump is a new type of pump and product developed by our company according to market demand. The pump solves the problem that the axial tension of the single-suction submersible pump is large and the mechanical seal is easy to leak in the case of higher head.

The WQS energy-saving double suction submersible sewage pump uses the side water of the common pump, and the flange installation structure can be either mobile installation or fixed installation by rail. Easy to install and maintain, with energy-saving, durable, anti-clogging, automatic installation and automatic control.

Because of the unique double-suction double-channel structure, the water pump in actual operation, water from both ends of the pump impeller at the same time, the middle outflow. The water inlet of the pump is divided into two parts, and the water is drawn from the bottom, and the suction level is low. Because water is absorbed from the upper and lower ends at the same time, and one end of the isolation oil chamber of the pump and the motor is in the suction port position, the isolation oil chamber has been in a negative pressure state during operation, and the mechanical seal of the single suction structure is more difficult to leak or damage, because the pump is absorbed from the upper and lower ends at the same time, so the motor has no axial tension, and the double runner structure is to reduce the radial force. So that its service life is extended, to achieve the use of durability, stability, practicality of the function.

The hydraulic performance of the double suction pump is mature, and the performance indicators of the product tested are much higher than the provisions of the relevant standard JB/T5118-2001, and a high standard enterprise standard has been formulated for the record (standard number: Q/TNTP001— 2010). After the product is put into the market, it is welcomed and praised by the majority of users with its unique effect, reliable performance and stable quality.

The pump distinguishes two series of water and sewage, and these two series are divided into ordinary type and out-of-band circulation cooling type and automatic mixing type three categories

【 Product Features 】

1. the series of double suction submersible pump, belongs to a submersible motor is a clever combination of double suction pump, so that it not only has the function of submersible pump, but also has the special performance of double suction pump running smoothly.

2. energy-saving double suction submersible sewage pump can meet the requirements of use in higher head occasions, because the mechanical seal is in a negative pressure state, with higher reliability and durability. The mechanical seal adopts double channel series sealing, the material is hard corrosion-resistant tungsten carbide, and has the characteristics of durability, which can make the pump run for more than 10,000 hours.

3. the use of double suction structure water absorption level is low, because of the use of double suction double runner structure, the motor has no axial tension, reduce and balance the radial force. The service life and efficiency of the pump are greatly improved.

4. WQS type pump with large flow channel anti-blocking components design, greatly improve the ability of dirt through, can effectively pass short fiber material and small diameter solid particles.

5. the pump structure is compact, small size, easy to move, easy to install, no need to build a pump room, diving into the water can work, greatly reducing the project cost.

6. the pump oil room is equipped with a water leakage probe, when the mechanical seal on the pump side is damaged, the water enters the oil chamber, and the probe signals to protect the pump.

7. can be equipped with automatic protection control cabinet according to user needs, the pump water leakage, leakage, overload and high temperature monitoring, pump reliable operation.

8. double rail automatic coupling system, to the installation and maintenance of the pump has brought great convenience, people do not need to enter and exit the sewage pit.

9. the float switch can automatically control the stop and start of the pump according to the required water level change, without special care.

10. the pump equipped with external circulating water device can work continuously for a long time in low water level occasions.

11. the pump equipped with self-mixing impeller, with self-mixing function, can stir the water in the pool, so that the sewage is mixed with the pump discharge.

12. There are two installation methods: fixed automatic coupling installation and mobile installation, which can meet different use occasions.

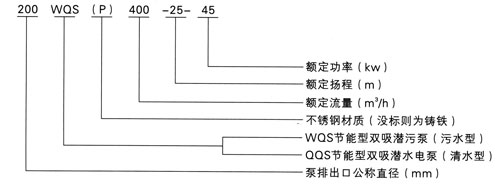

【Model significance】

【 Scope of use 】

1. factory commercial serious pollution wastewater discharge

2. urban sewage treatment plant drainage system

3. residential sewage drainage station

4. fire system drainage station

5. hospital, hotel sewage discharge

6. municipal engineering, construction site

7. exploration, mining supporting machine

8. rural biogas pond farmland watering.

9. Water supply device of water works

【 Working conditions 】

1. the medium temperature is less than 60%, the weight is 1.0 ~ 1.3 kg/d m 3, and the P H value is in the range of 5 ~ 9.

2. no external circulation cooling system of the pump, the motor part of the liquid surface is only 1/20.

3. under normal circumstances, the pump must be used in the normal use of the head range (usually not less than 70% of the rated value), the motor is not loaded, if it needs to be used in the full head range, it should be noted separately when ordering, so that the manufacturer can manufacture.

4. The current of the pump motor shall not exceed the rated current of the motor during operation.

Product related documents:

If you want to learn more about the WQS Energy saving double suction submersible sewage pump, please click the link below to view

【WQS energy-saving double suction submersible sewage pump structure description】The structure and name of each part of WQS energy-saving double suction submersible sewage pump are introduced.

【WQS energy-saving double suction submersible sewage pump performance parameter table】The data of flow, head, power and efficiency corresponding to each specification of WQS energy-saving double suction submersible sewage pump are introduced.

【WQS energy-saving double suction submersible sewage pump mounting dimensions】The installation dimensions and flange connection dimensions of each specification of WQS energy-saving double suction submersible sewage pump are introduced.

【WQS energy-saving double suction submersible sewage pump instructions】This paper introduces the matters needing attention in the installation and use of WQS energy-saving double suction submersible sewage pump and the common troubleshooting methods.

If you are interested in WQS Energy saving Double suction submersible sewage pump products, please downloadWQS energy saving double suction submersible sewage pump electronic sample,So that you can check at any time!

Home

Home Tel

Tel Product

Product