In-line pump

Number of views:13

QR code:

Add time:2025-04-10

Brief:

Product overview

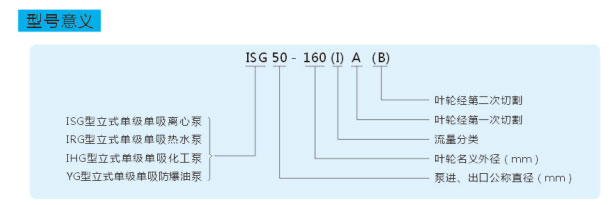

Single-stage single-suction vertical centrifugal pump IS the company's IS type centrifugal pump performance parameters and vertical pump structure, in strict accordance with the international quasi-IS02858 and national standards successfully designed energy-saving products, is to replace IS type horizontal pump, D pump and other conventional products of the novel vertical centrifugal pump.

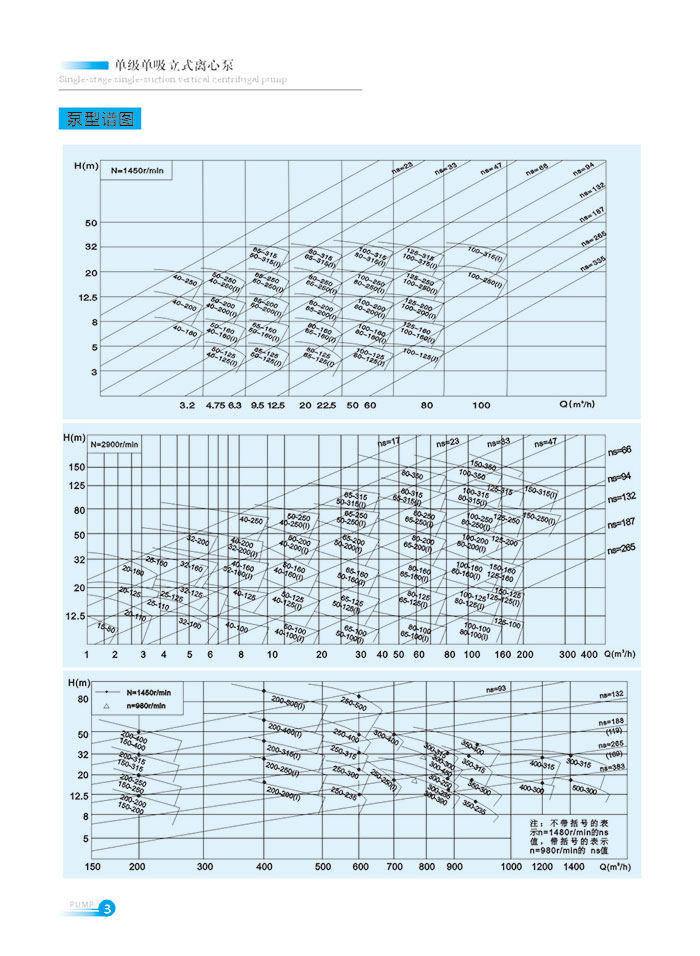

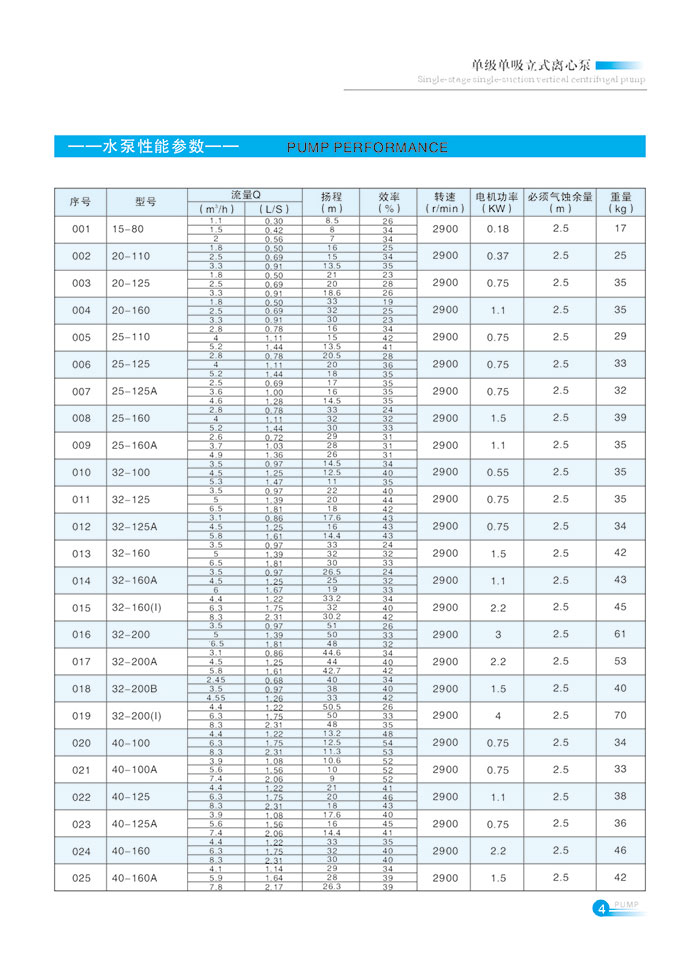

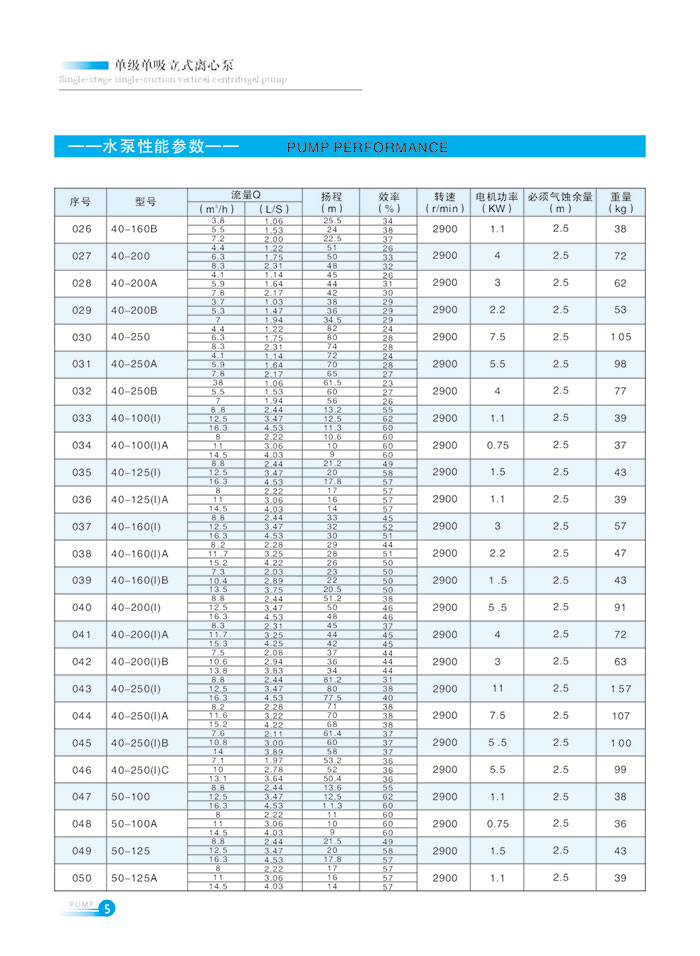

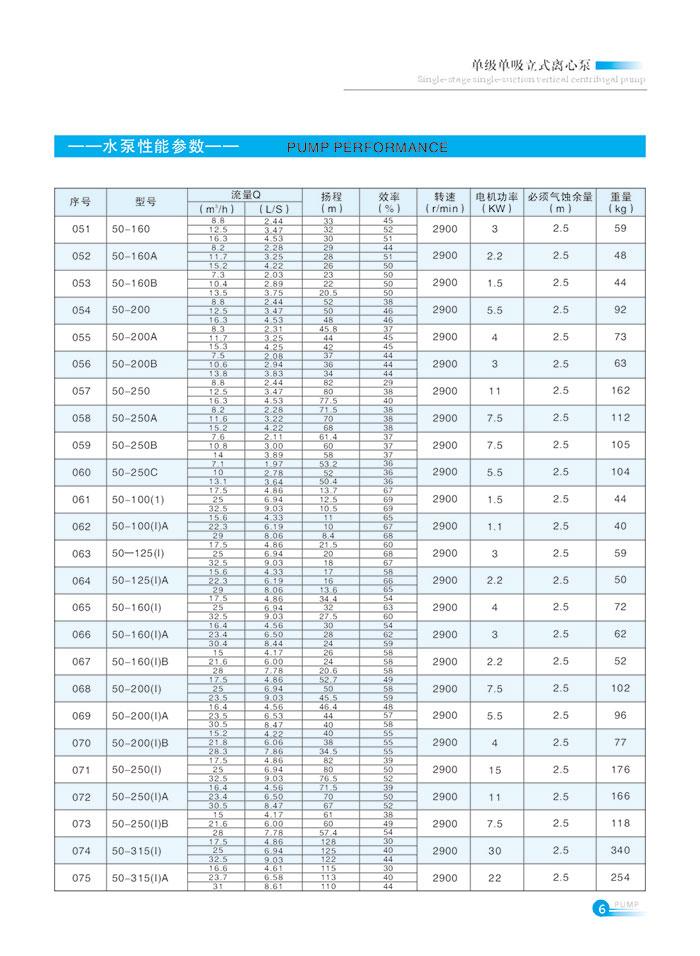

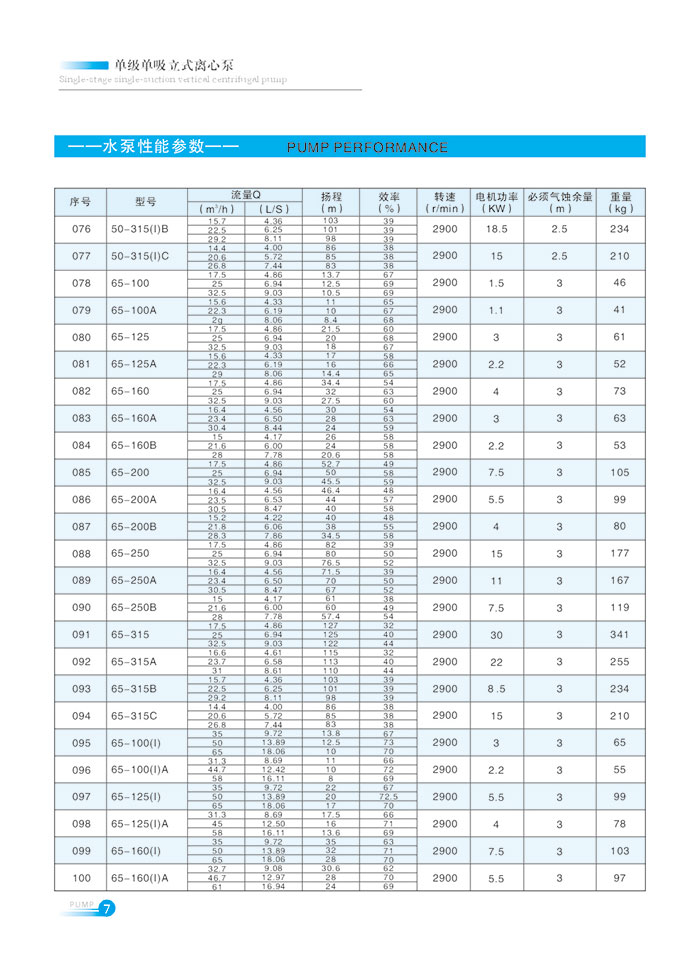

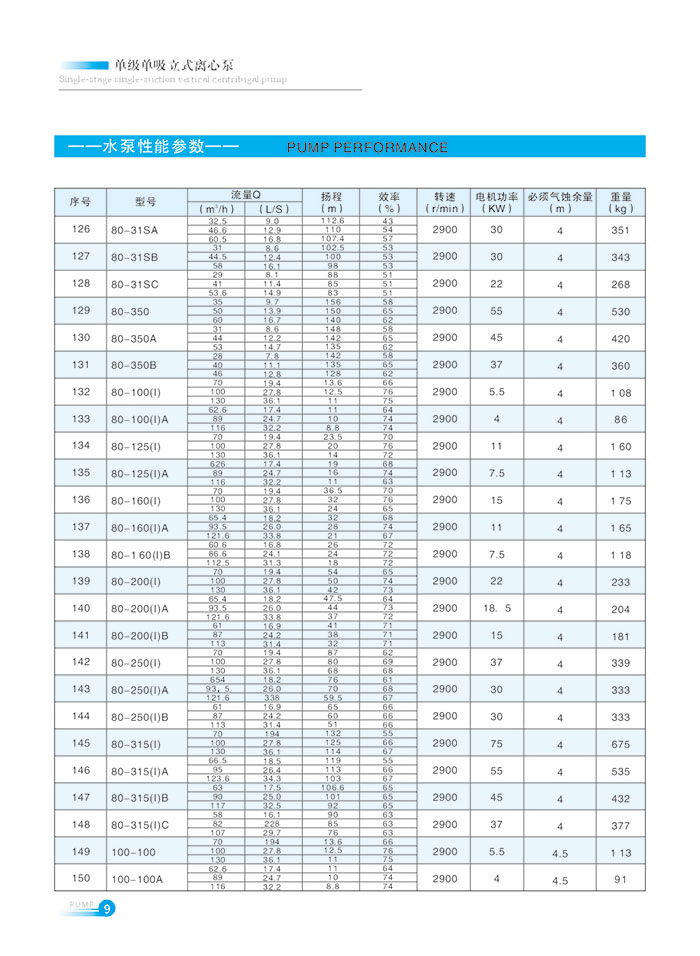

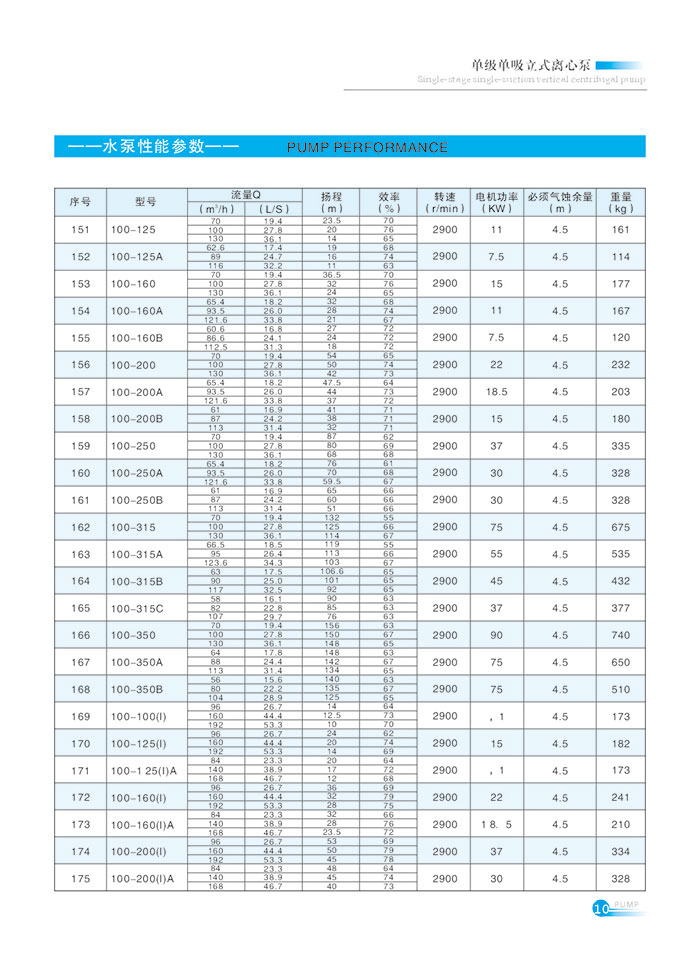

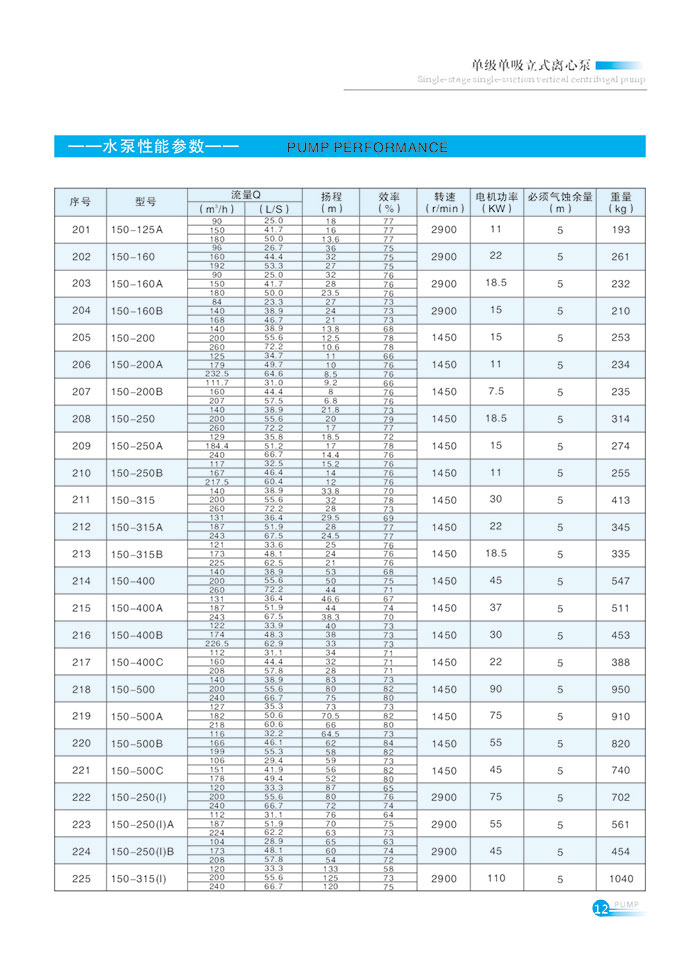

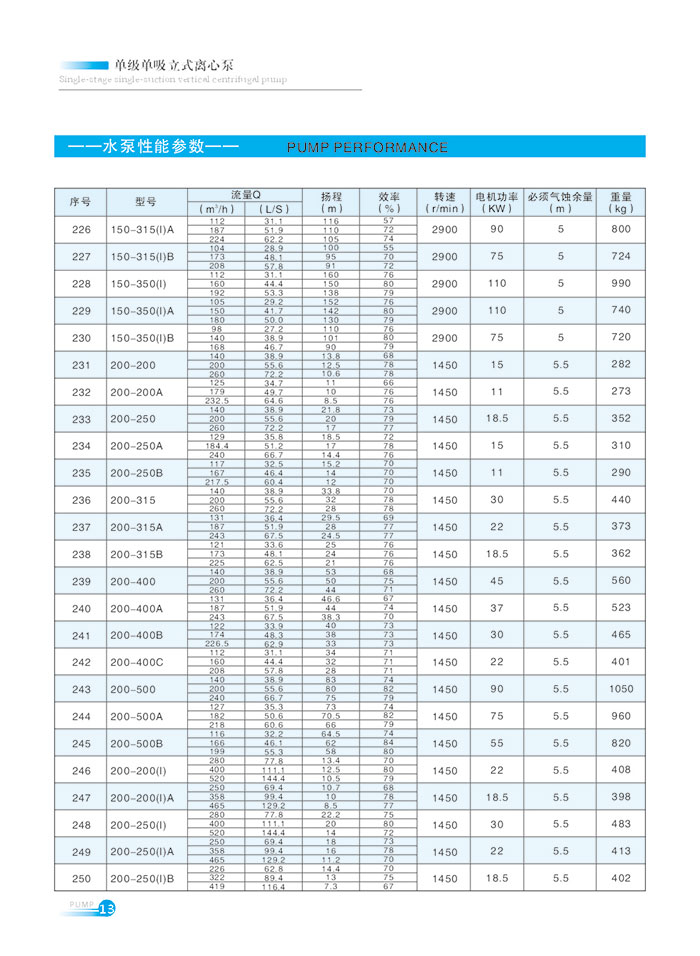

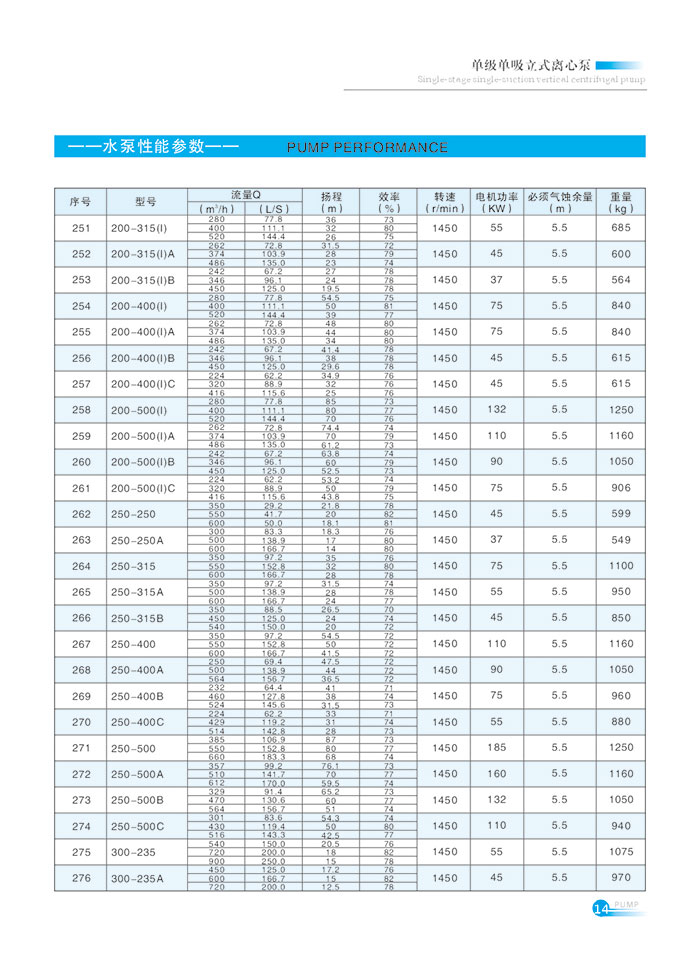

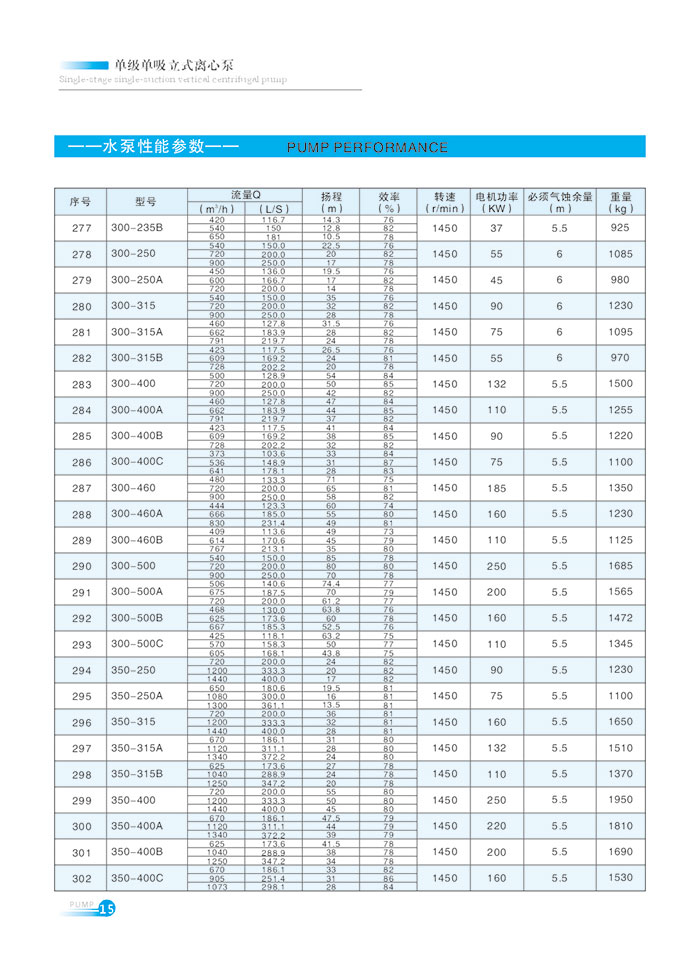

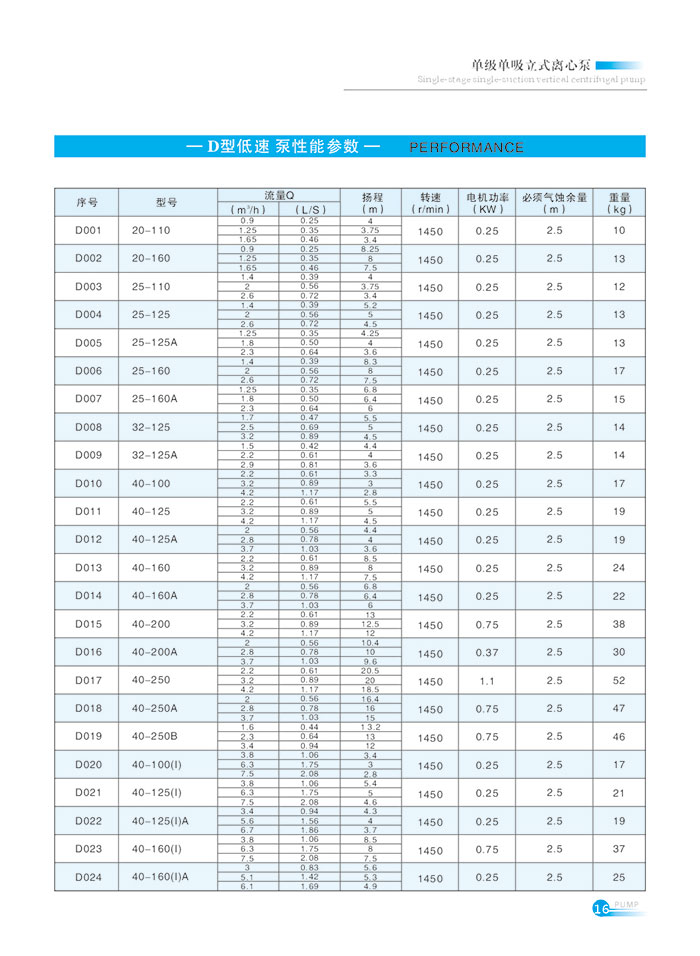

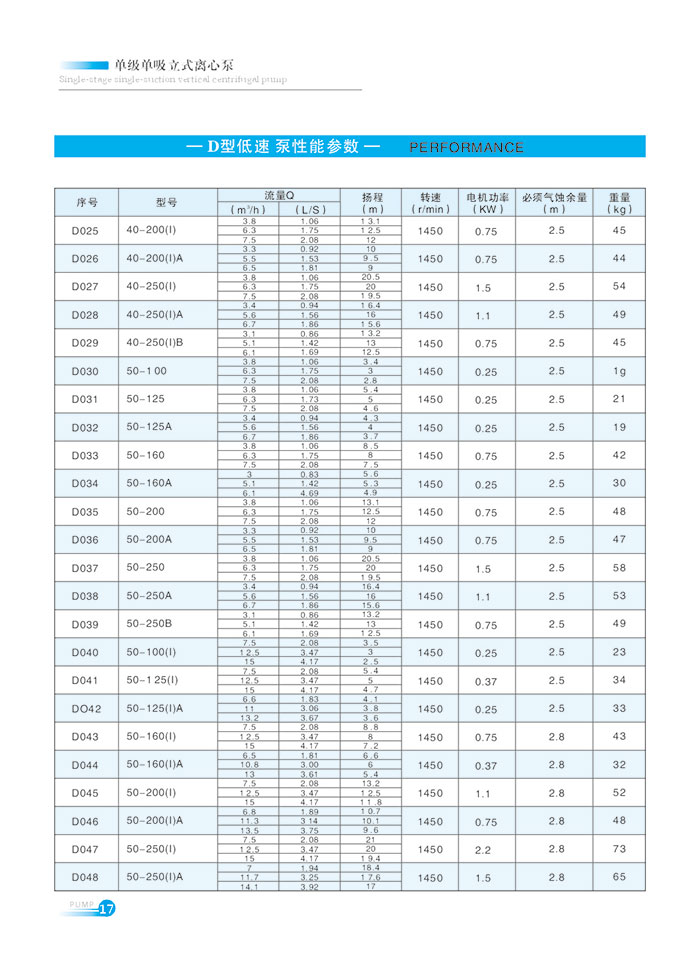

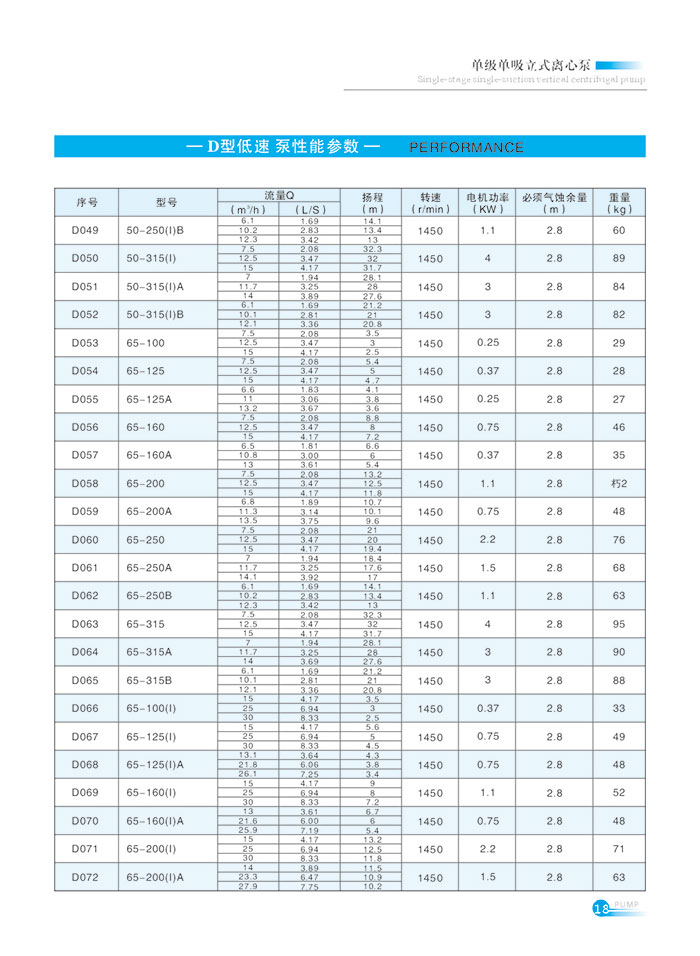

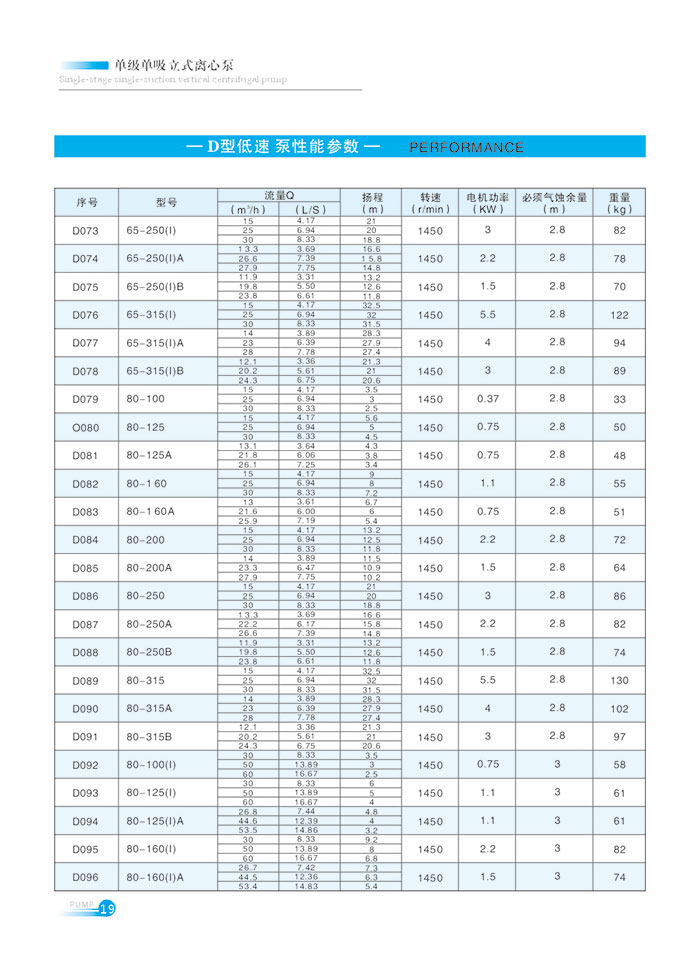

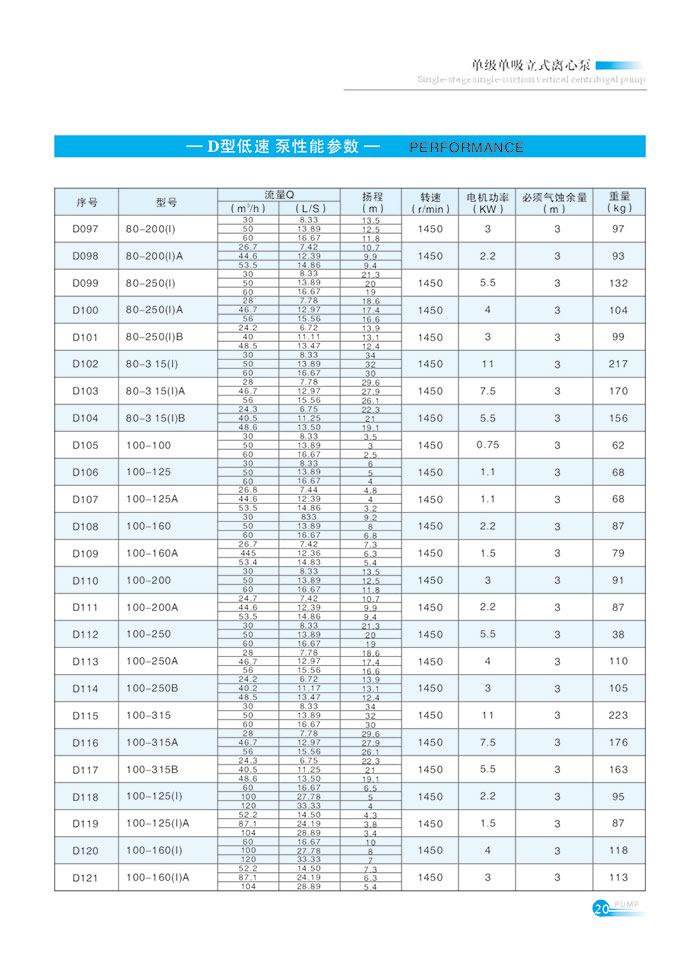

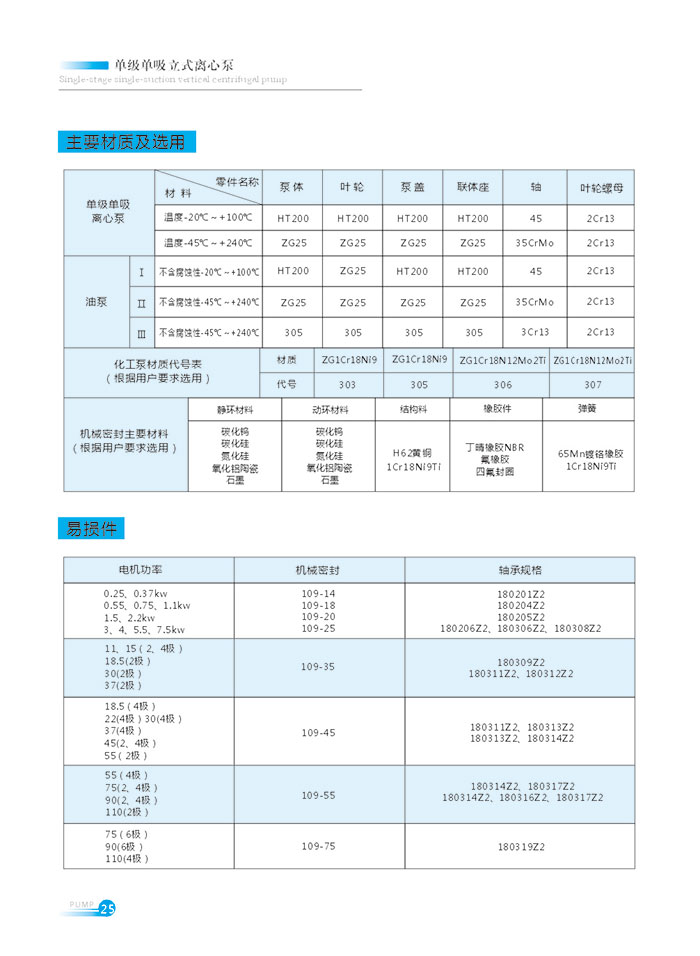

Flow range 1.5~1200m7h, head range 8-150m, divided into basic type, expanded flow type, A,B,C cutting type and other 250 kinds of specifications. According to the different flow medium and temperature, design and manufacture into the same performance parameters of hot water pump, chemical pump, oil pump and explosion-proof chemical pump series products.

Product characteristics

1. The pump structure is compact, small size, beautiful appearance. Its vertical structure enhances the operational stability and life of the pump.

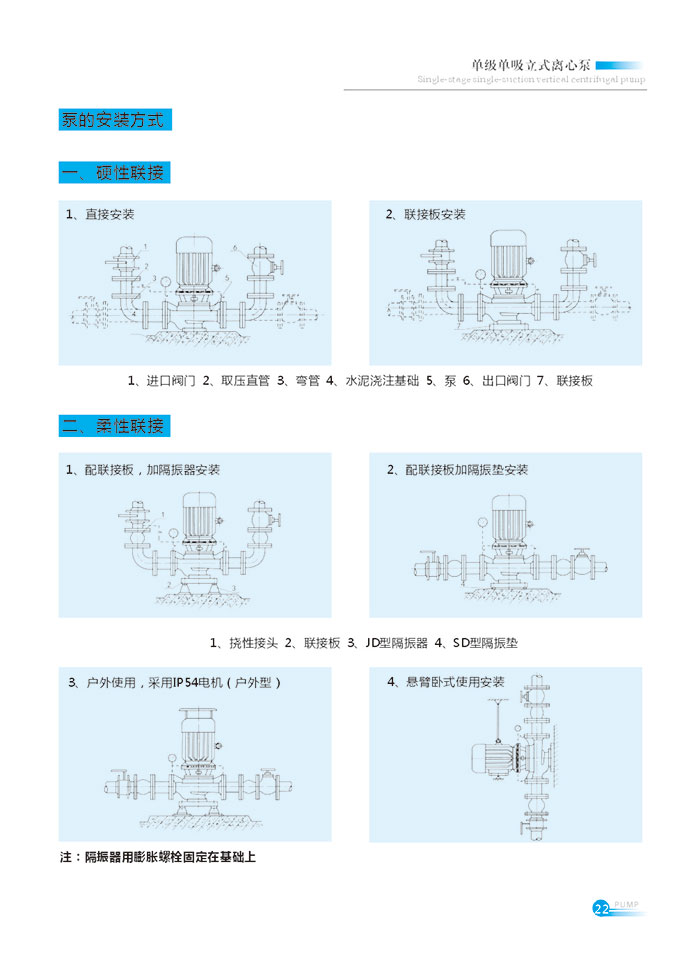

2. Easy to install. The inlet and outlet caliber is the same and on the same line can be directly installed in any part of the pipeline like a valve. The motor can be placed outdoors with a rain cover. The pump is provided with a mounting foot for stable installation of the pump.

3. Smooth operation, low noise, high concentricity of components. The motor adopts low noise bearing and is equipped with non-stop refueling device. The impeller of the pump has good dynamic and static balance, and the operation has no vibration to improve the use of the environment.

4. No leakage. The shaft seal adopts corrosion-resistant cemented carbide mechanical seal to solve the serious problem of leakage of centrifugal pump packing seal and extend the service life to ensure that the operating site is clean and tidy.

5. Easy maintenance. No need to remove pipe. Just remove pump cover. Take out the motor and transmission components for repair and maintenance.

6. According to the field conditions of use pump can be vertical, horizontal, multi-mode installation according to the flow head requirements • Use and series method, increase the required flow head.

Working condition

1. The high working pressure of the pump system is < 1.6MPa.BD pump inlet pressure + pump head < 1.6MPa. Please indicate system working pressure when ordering. When the inlet pressure is large T1.6MPa, it should be proposed separately at the time of ordering, so that the flow part and the connection part of the pump are made of cast steel.

2. Applicable medium: clean water pump medium should be non-corrosive liquid, medium solid insoluble matter, its volume is but 0.1% per unit volume, particle size < 0.2mm0, such as the medium with fine particles, please specify when ordering.

3. The ambient temperature is only 4 (PC), the relative humidity is only 95%.

Main use

1. Vertical single-stage single-suction centrifugal pump is used for conveying water and other liquids with physical properties similar to water. Use medium temperature below 80℃. It is suitable for industrial and urban water supply and drainage, pressurized water supply in high-rise buildings, garden sprinkler irrigation, fire pressurization, long-distance water transmission, heating, bathroom cold and warm water circulation pressurization and equipment matching.

2. Vertical single-stage single heat pump is suitable for heating system of civil and enterprises and institutions building housing heating and hot water pressurization, circulation, transportation and other production processes with thermal systems, such as: power station, thermal power station, waste heat utilization, metallurgy, chemical industry, textile, wood processing, paper and other industrial boilers high temperature hot water, the use of temperature below 105℃.

3. Vertical single-stage single-suction chemical pump, transport does not contain solid particles with corrosive viscosity similar to water liquid. Applicable to textile, petroleum, chemical, metallurgy, electric power, paper, food,

Pharmaceutical and synthetic fiber departments, the use of temperature -20℃~120℃.

4. Vertical single stage single suction explosion-proof oil pump is suitable for petroleum, textile, chemical, machinery and other industries to transport non-corrosive, flammable, explosive liquid transport medium temperature -20℃~120℃.

5. Vertical single stage single suction explosion-proof chemical pump does not contain solid particles with corrosive viscosity similar to water and flammable and explosive liquid. Suitable for textile, petroleum, chemical, metallurgy, mining, pharmaceutical and synthetic fiber departments, the use of temperature -20℃~120℃.

Pump installation instructions

1. the weight of the pipeline should not be borne on the pump, otherwise it is easy to damage the pump; The pump and motor are the whole structure of the factory has been corrected by the manufacturer when the installation does not need to be adjusted • so the installation is very convenient;

2. the installation must be tightened and the base dipper column should be checked every certain period of time to prevent it from loosening, so as to avoid vibration when the pump starts and affect the performance of the pump:

3. Before installing the pump, carefully check whether there are hard objects (such as stones, iron sand, etc.) in the pump channel that affect the operation of the pump, so as not to damage the flow parts during the operation of the pump

4. in order to facilitate the use and maintenance of the pump inlet pipe on the installation of a regulating valve and the installation of a pressure gauge near the pump outlet • For high lift pump, for the waterproof hammer, should also be installed before the outlet gate valve a check valve to cope with sudden power failure and other loss of power accidents, so as to ensure that the pump operates under working conditions, extend the service life of the pump.

5. the pump is used for suction occasions, should be equipped with a bottom valve • and the entrance mouth should not have too many elbows, while there should be no water leakage, leakage phenomenon so as not to affect the suction of the pump; In order to prevent impurities from entering the pump and blocking the flow channel, a filter should be installed before the pump entry port.

6. Rotate the rotor components of the pump before installing the Ying road. There should be no friction sound or Calle phenomenon, otherwise the pump should be disassembled to check the cause.

Pump starting and stopping

▲ Preparation before starting

1. the hand to turn the motor wind blade wheel should be flexible, no card friction phenomenon;

2. fully open the inlet valve, open the exhaust valve to fill the pump chamber with liquid, and then close the exhaust valve;

3. check whether the parts are normal, whether the bearing is well lubricated, whether the bushmaster plug is tight in each part, and whether the suction tube is smooth;

4. if the medium temperature is high, it should be preheated, and the heating speed is 5CTC/h to ensure that all parts are evenly heated.

▲ Start and run

1. Fully open the inlet valve, close the discharge pipe valve, and start the motor (pay attention to whether the rotation is correct);

2. after the unit speed is stable, adjust the opening of the valve, observe the pressure gauge, the flow meter, and check the shaft seal leakage;

3. check the motor, bearing temperature rise S7O°C, if abnormal should be handled in time.

▲ Park

1. when the medium temperature is high, it should be cooled first, the cooling speed is 10°C/min, and the liquid temperature can be stopped before it drops below 7CTC;

2. close the outlet valve, while closing the vacuum gauge and pressure gauge cock;

3. cut off the power supply, close the inlet valve;

4. such as long-term parking should exhaust the liquid in the pump, especially in the environment temperature is lower than (TC) should immediately exhaust the liquid after parking, in order to prevent frost damage parts.

Pump maintenance and maintenance

▲ Maintenance and maintenance in operation

1. the water inlet pipe must be highly sealed, no water leakage, air leakage; It is forbidden to run the pump in the cavitation state;

2. try to avoid the pump in large flow conditions; Periodically check the motor current value shall not exceed the rated motor current;

3. the pump should be supervised during operation to avoid accidents: the pump refueling bearing everyday every 5000 hours:

4. After long-term operation of the pump, when the noise and vibration of the unit increase due to mechanical wear, it should be stopped for inspection. • When needed, the wearing parts can be replaced.

▲ Mechanical seal maintenance and maintenance

1. mechanical seal lubrication should be clean without solid particles; It is strictly forbidden for the machine and machine seal to work under dry grinding conditions;

2. before starting should drive the pump (motor) a few laps to avoid sudden start caused by mechanical seal fracture damage;

3. sealing leakage tolerance is 3 drops/min, otherwise it should be repaired.

Home

Home Tel

Tel Product

Product