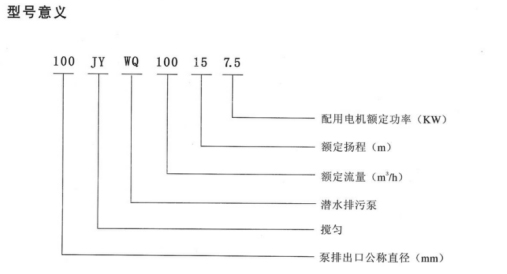

Submersible sewage pump

Number of views:33

QR code:

Add time:2025-04-10

Brief:

Product overview

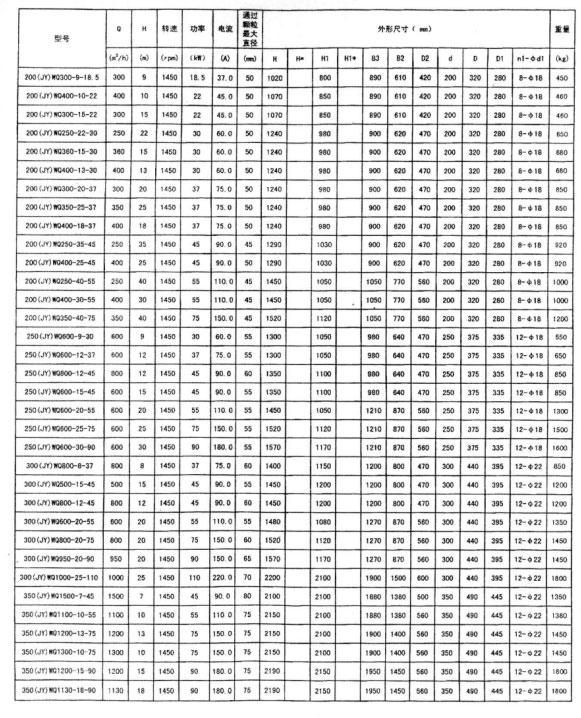

WQ type non-clogging submersible sewage pump is a new-generation pump product successfully developed on the basis of the introduction of foreign technology and combined with the characteristics of domestic pumps. It has the characteristics of anti-winding, non-clogging, automatic installation and automatic control. It is effective in discharging solid particles and long fiber waste.

With a unique impeller structure and a new mechanical seal, this series of pumps can effectively transport solids and long fibers. Compared with the traditional impeller, the impeller of the pump adopts the form of single channel or double channel, which is similar to a curved pipe of the same size and has very good flow performance, and is equipped with a reasonable cochlear chamber, which makes the pump with high efficiency, and the impeller is tested by dynamic and dynamic balance, so that the pump has no vibration in operation.

The hydraulic performance of the pump is mature, and the performance indicators of the product have reached the relevant standards, and the product has been welcomed and praised by the majority of users after being put on the market with its unique effect, reliable performance and stable quality.

Product characteristics

1. the use of large flow channel anti-blocking hydraulic component design, greatly improve the ability of dirt through, can effectively through the pump diameter of 5 times the fiber material and the diameter of the pump port: about 50% of the diameter of solid particles.

2. reasonable design, matching motor reasonable, high efficiency, energy saving effect is remarkable.

3. the pump shaft by chrome plating treatment greatly improve the shaft corrosion resistance, wear resistance, the service life of the whole pump has been significantly improved.

4. the cable and the motor are connected by the rubber sleeve integral vulcanization technology, its waterproof effect is long-term and reliable.

5. the mechanical seal uses double channel series sealing, the material is hard corrosion-resistant tungsten carbide, durable and other characteristics, can make the pump run continuously for more than 8000 hours.

6. the pump structure is tight, small size, easy to move, easy to install, no need to build a pump room. Diving into the water can work, greatly reducing the cost of the project.

7. the pump oil room is equipped with oil and water probe, when the pump side mechanical seal is damaged, water into the oil chamber, probe signal, the pump protection.

8. can be equipped with automatic protection control cabinet according to user needs, the pump water leakage, leakage, overload and high temperature monitoring, so that the pump reliable operation.

9. double rail automatic coupling installation system, to the installation and maintenance of the pump has brought great convenience, people can not enter and exit the sewage pit for this.

10. the float switch can automatically control the stop and start of the pump according to the required water level change, without special care.

11. Let the motor run without load within the range of the use head.

12. according to the use of the motor can use water jacket type external circulation cooling system, which can make the electric pump run in a water-free (dry) state.

13. the installation method has two kinds of fixed automatic coupling installation and mobile free installation, which can meet different use occasions.

Product application

1. the factory commercial serious pollution wastewater discharge.

2. urban sewage treatment plant drainage system.

3. Sewage drainage stations in residential areas.

4. civil air defense system drainage station.

5. hospital, hotel sewage discharge.

6. Municipal engineering and construction sites.

7. exploration, mining equipment.

8. Farmland irrigation of rural biogas digester.

9. Water supply device of water works.

Pump service condition

1. the medium temperature is not more than 60℃, the severity is 1.0~1.3kg/dm', and the PH value is in the range of 5~9.

2. there is no internal flow circulation cooling system of the pump, the motor part of the liquid surface is only 1/2.

3. under normal circumstances, the pump must be used within the range of the use of the head, so that the motor is not loaded, if it needs to be used in the full head range, it should be indicated separately when ordering, so that the manufacturer can manufacture.

4. The current of the pump motor shall not exceed the rated current of the motor during operation.

Structure specification

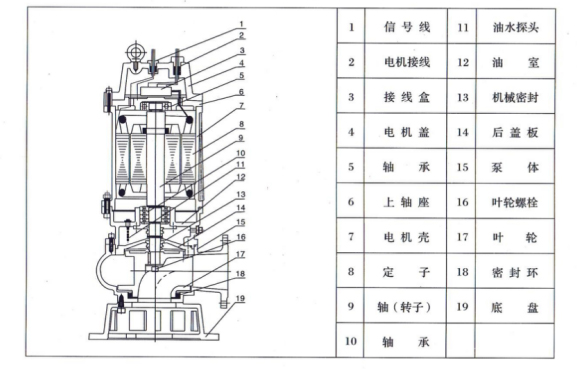

WQ type non-clogging submersible sewage pump is composed of two parts: motor and pump, separated by oil isolation chamber and mechanical seal assembly, belongs to electromechanical and bulk products. Motor and pump coaxial (rotor) The whole pump length is short, compact structure. Equipped with a variety of protection devices, making the pump reliable operation. Its main components function as follows:

Signal line 1: Equipped with a fully protected pump control cabinet to protect the pump, including water leakage, phase break, short circuit, overheating, motor overload and other items.

Motor stator 8: Class B or F insulation.

Water leakage probe 11: The component is installed in the oil chamber, when the mechanical seal is damaged, water enters the oil chamber, the probe can send a signal by the control system to protect the pump.

Mechanical seal 13: double channel series sealing, the selection of new hard corrosion-resistant tungsten carbide material, with reliable sealing, long life and other characteristics.

Impeller 17: The impeller adopts single channel or double channel structure, has a strong passing capacity, can pass large materials and fiber waste: reduce blockage. The winding fault.

Pump body 15: with the impeller, so that the pump has a high efficiency.

Seal ring 18: installed in the mouth ring of the pump body, when the impeller is worn due to the operation of the mouth ring, the seal ring can be replaced to make the pump run efficiently.

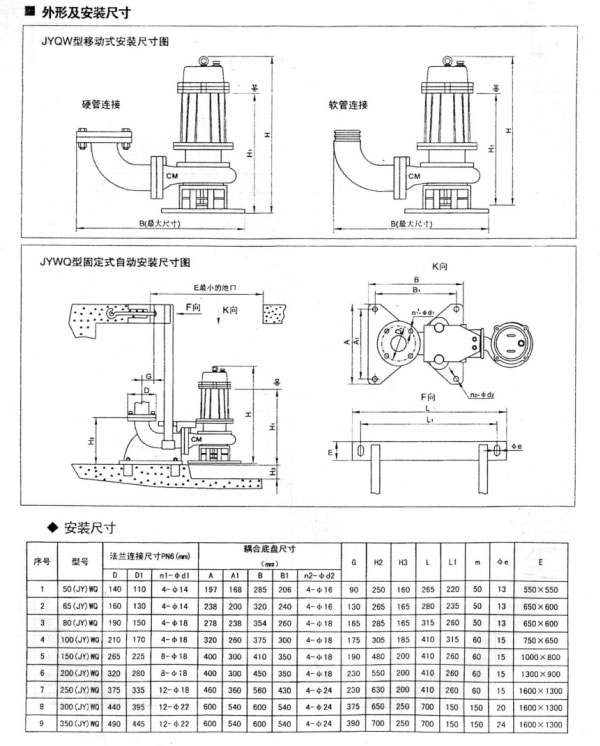

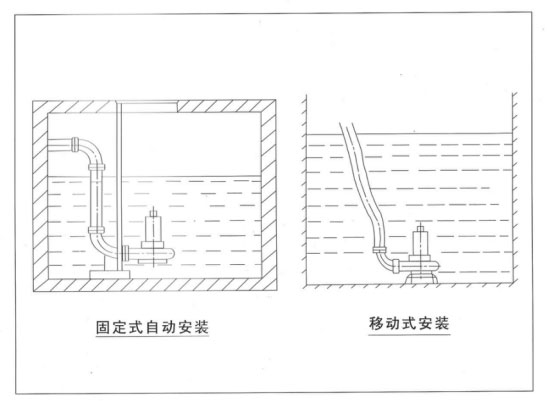

Installation system Description

1. automatic coupling device system

It is suitable for the use of long fixed occasions, with the advantages of quick installation, convenient detection and maintenance. The system uses a special base, fixed at the bottom of the sump, connected with the outlet pipe, installed supporting blocks in the pool, connected with a guide rod, the pump is connected to a specific support, along the guide rod to reach the base, automatically coupled and sealed, and automatically dropped off when lifting.

2. Mobile installation system

It supports water with a support, and can work by pressing the outlet hose, which is mainly used for emergency or maintenance construction needs.

Pump use method and precautions

1. Before using the pump, carefully check whether the cable is damaged, whether the fasteners are loose or fall off, and whether the pump is deformed or damaged during dynamic transmission, storage and installation.

2. Use a 500V megohm meter to measure the insulation resistance between the same and relative ground of the electric pump motor, and its value should not be less than 2 megohm, otherwise the stator windings of the motor should be dried, and the temperature of the drying treatment is not allowed to exceed 120℃.

3. The installation of this series of pumps is fixed and mobile. When the fixed automatic installation is used, the chain cable should be inserted into the two ring screws or lifting plates (deviating from the pump water outlet, and the connection should be parallel to the pump water outlet) to lift the electric pump. The hook slowly slides along the guide rail until the automatic coupling is in place. When the mobile installation is used, the hose is first set, and the chain cable is inserted into the two lifting rings to lift the electric pump, and it is noted that the cable cannot be used as a rope to avoid danger.

4. The rotation direction after the pump is connected from the water inlet is seen as counterclockwise rotation, if the pump is reversed, just switch any two wires in the cable line to the wiring position.

5. The ground wire of the electric pump housing shall be properly connected in strict accordance with the relevant regulations. In order to ensure personal safety when the electric pump is in operation, it is strictly forbidden to work or move the installer in the water nearby. In case of an accident on the leakage surface of the electric pump.

6. The electric pump must be equipped with automatic pump control cabinet in no special circumstances, do not directly hang the power grid or use the knife switch to switch on the power to ensure the normal operation of the electric pump.

7. The electric pump shall not be operated in a low lift state for a long time (the general use of the lift shall not be less than 60% of the rated lift), and it shall be controlled within the recommended range of the lift to prevent the overload of the electric pump from burning out the motor.

8. The pump without self-circulating cooling device is strictly prohibited from long-term operation above the water surface as a whole to prevent the electric pump from overheating and damage.

Maintenance

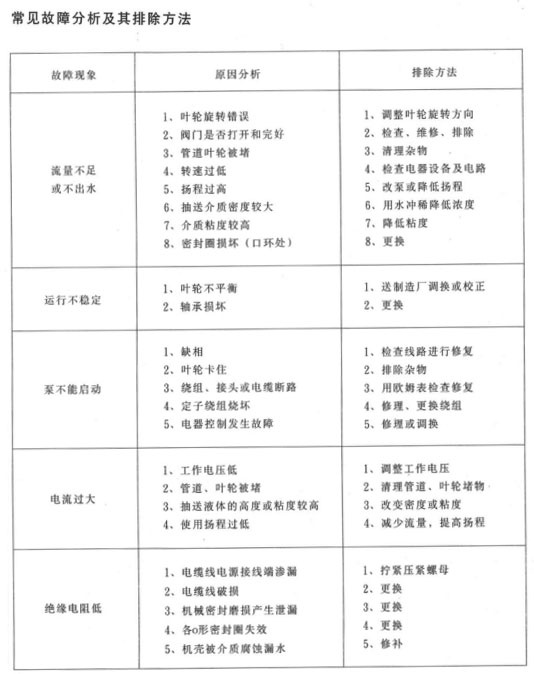

1. The electric pump should be managed and used by special personnel, and regularly check whether the insulation resistance between the electric pump winding and the housing is normal.

2. After each use, especially for thicker and more viscous slurry, the electric pump should be put into clean water for a few minutes to prevent deposits from being left in the pump and clean the electric pump.

3. If the electric pump is not used for a long time, the electric pump should be removed from the water, and it should not be soaked in water for a long time to reduce the chance of moisture in the stator windings of the motor and increase the service life of the electric pump.

4. In the conventional state, the pump should be filled or replaced after 300 to 500 hours of oil (10 to 30 oil) in the oil chamber, so that the mechanical seal maintains a good lubrication state and improves the use of the mechanical seal.

5. After the disassembly and maintenance of the electric pump, the housing components must be checked by 0.2MPa 'airtight test to ensure that the motor seal is reliable.

6. The sealing ring between the impeller and the pump body has a sealing function, such as seal damage will directly affect the performance of the pump, should be replaced when needed.

Electrical control system of water pump

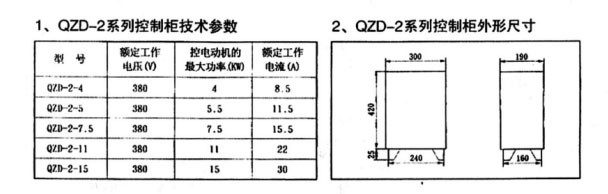

QZD-2 series pump control cabinet

(2D-2 series control cabinet control 0.75~150W single pump electrical part, with control pump start and stop, pump motor overload, short circuit, lack of phase, high temperature, phase break and water leakage monitoring and protection.

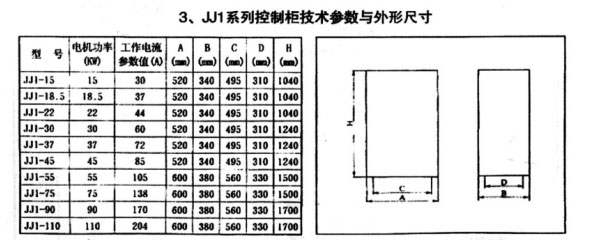

J1 series pump control cabinet

JJ1 series pump control cabinet controls 15~110K pump motor for automatic automatic decompression start, with short circuit, phase loss, overload and other multi-park protection functions for motor stator high temperature protection and water leakage protection for pump oil chamber.

This catalog describes that the control cabinet is a single pre-automatic control cabinet, such as two pumps, three pumps, four pumps and multiple pumps mixed - - cabinet control and pump control cabinet equipped with other functions, please submit a separate negotiation when ordering, and the external size of the control cabinet is selected by referring to the sum of the corresponding control power.

Home

Home Tel

Tel Product

Product