ZWL type direct connected self-priming non-clogging sewage pump

Number of views:12

QR code:

Add time:2025-04-10

Brief:

Product characteristics

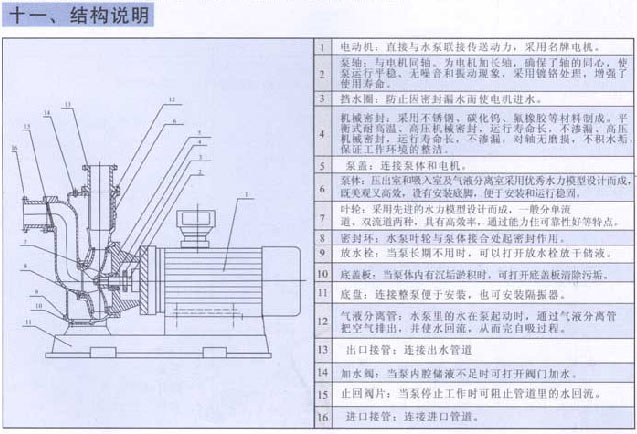

ZWL type direct connected self-priming non-clogging sewage pump adopts direct connected structure compared with similar domestic production, has the characteristics of simple and compact structure, less vibration, good self-priming performance, strong sewage capacity, energy saving, convenient use and maintenance.

Product overview

ZWL type direct-connected self-priming non-clogging sewage pump is a novel product developed successfully on the basis of repeated research on similar technologies at home and abroad. ZWL type direct-connected self-priming non-blocking sewage pump set self-priming and non-blocking sewage in one, the use of axial return external mixing, and through the unique design of pump body, impeller flow channel, can be like the general self-priming clean pump does not need to install the bottom valve and irrigation water, but also can suck and drain containing large particles solid and long fiber impurities liquid. It can be widely used in municipal sewage engineering, river pond culture, light industry, paper making, textile, food, chemical industry, electricity industry, fiber, slurry and mixed suspension and other chemical media ideal impurity pump.

Compared with similar domestic products, the pump has the characteristics of simple and compact structure, less vibration, good self-priming performance, strong sewage capacity, energy saving, convenient use and maintenance. The technical performance index is higher in China, and it has broad application market and development prospect.

Performance parameter

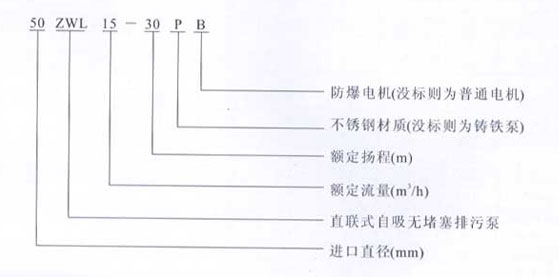

Type description

Scope of use

1. The ambient temperature ≤50℃, medium temperature ≤80℃ special requirements up to 200℃.

2. The medium PH value of cast iron material is 6-9, stainless steel is 2-13.

3. The medium weight is no more than 1240 kg /m3.

4. The self-priming height can not exceed the specified value of 4.5-5.5 meters, the length of the suction tube is less than 10 meters.

5. The diameter of suspended particles through the capacity is 60% of the pump caliber, and the fiber length is 5 times of the pump caliber.

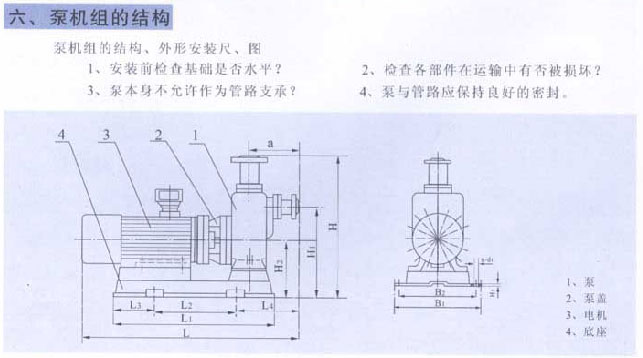

The structure of the pump unit

1. Check whether the foundation is level before installation.

2. Check whether the parts have been damaged during transportation.

3. The pump itself is not allowed to be used as a pipeline support?

4. Pump and pipeline should be kept well sealed.

Home

Home Tel

Tel Product

Product