ZS Double Suction Self-priming Pump (split type)

Number of views:15

QR code:

Add time:2025-04-10

Brief:

Product characteristics

The pump can use split type and direct type and disassembly type three kinds of structure, according to the type is divided into water type, sewage type two series, compared with similar products in China, with simple and compact structure, small vibration, good self-priming performance, strong sewage capacity, energy saving, easy to use and maintenance.

Product overview

ZSL strong self-priming. High lift. Large flow. Direct-connected double priming self-priming pump is a new energy-saving double priming self-priming pump product developed by our company according to market demand. ZSL strong self-priming. High lift. Large flow. Direct-connected double priming self-priming pump solves the problems of large axial tension, long self-priming time and low efficiency of single-priming self-priming pump. It has the advantages of high suction range, short self-priming time, high efficiency, remarkable energy-saving effect, stable operation and long service life. AYZS clean water type is suitable for the transport of clean water or light sewage occasions, higher efficiency than sewage type, good self-priming performance. AYZSW sewage pump integrates self-priming and non-clogging sewage, adopts axial return mixing, and through the unique design of pump body and impeller flow channel, it does not need to install bottom valve and irrigation water, but also can suck and drain liquid containing particles solid and fiber and other impurities. It can be widely used in municipal sewage engineering, lotus pond culture, light industry, paper making, food, chemical industry, electricity industry, fiber, slurry and mixed suspension and other chemical media ideal impurity pump. AYZSC diesel double suction self-priming pump is suitable for a variety of complex emergency rescue, fire and other occasions, not affected by the power supply, the use of the site and other factors, can move operation, high flexibility.

Performance parameter

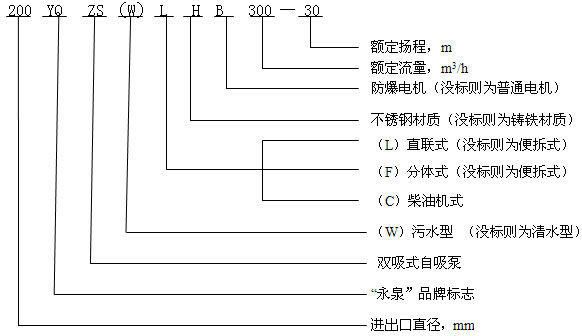

Type description

ZSL strong self-priming. High lift. Large flow. Direct connection double priming self-priming pump range of use

1. ambient temperature ≤ 50℃, medium temperature ≤ 80℃ Up to 200 ℃ for special requirements.

2. the medium PH value of cast iron material is 6 ~ 9, stainless steel is 2 ~ 13.

3. AYZSW sewage type double suction self-priming pump using medium weight of 1240kg/m3, sewage type of the same type of pump head is less than 10% of the water type

4. the self-priming height can not exceed the specified value of 5 ~ 7 meters, the length of the suction tube is ≤ 10m.

5. AYZSW sewage type double suction self-priming pump through the capacity of suspended particles diameter is about 20% of the pump caliber, fiber length pump caliber 5 times.

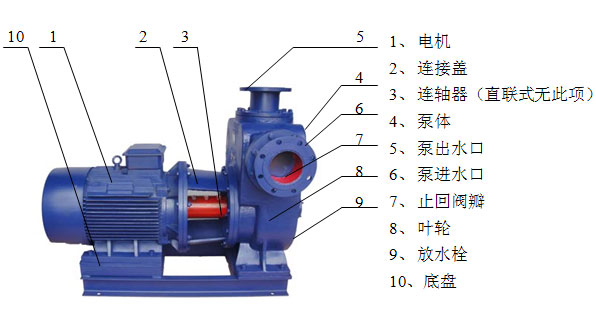

ZSL strong self-priming. High lift. Large flow. Direct connection double priming self-priming pump pump structure diagram

Parametric chart

| Serial number | model | Flow rate m3/h | Head m | efficiency % | Power kW | Speed n r/min | Cavitation margin m | Self-priming height m | Self-priming time (S/5m) | weight |

1 | 100ZSL80-10-4.2-4 | 80 | 10 | 68.1 | 4 | 1450 | 2.0 | 5.5 | 100 | 230 |

2 | 100ZSL100-12-5.5-4 | 100 | 12 | 74.3 | 5.5 | 1450 | 2.5 | 6.0 | 100 | 260 |

3 | 100ZSL100-15-7.5-4 | 100 | 15 | 68.1 | 7.5 | 1450 | 2.5 | 6.0 | 100 | 280 |

4 | 100ZSL100-20-11-4 | 100 | 20 | 66.1 | 11 | 1450 | 2.5 | 6.5 | 100 | 320 |

5 | 100ZSL100-25-15-4 | 100 | 25 | 60.6 | 15 | 1450 | 2.5 | 7.0 | 100 | 330 |

6 | 100ZSL100-30-18.5-4 | 100 | 30 | 58.9 | 18.5 | 1450 | 2.5 | 7.0 | 100 | 360 |

7 | 100ZSL100-40-22-2 | 100 | 40 | 66.1 | 22 | 2900 | 2.5 | 7.0 | 100 | 360 |

8 | 100ZSL100-50-30-2 | 100 | 50 | 60.6 | 30 | 2900 | 2.5 | 7.0 | 100 | 440 |

9 | 100ZSL100-60-37-2 | 100 | 60 | 63.1 | 37 | 2900 | 2.5 | 7.0 | 100 | 450 |

10 | 100ZSL100-70-45-2 | 100 | 70 | 60.6 | 45 | 2900 | 2.5 | 7.0 | 100 | 530 |

11 | 100ZSL100-80-45-2 | 100 | 80 | 64.6 | 45 | 2900 | 2.5 | 5.5 | 100 | 540 |

12 | 150ZSL150-10-7.5-4 | 150 | 10 | 68.1 | 7.5 | 1450 | 2.5 | 6.0 | 100 | 330 |

13 | 150ZSL150-15-11-4 | 150 | 15 | 69.7 | 11 | 1450 | 2.5 | 6.0 | 100 | 340 |

14 | 150ZSL150-20-15-4 | 150 | 20 | 68.1 | 15 | 1450 | 2.5 | 6.5 | 100 | 370 |

15 | 150ZSL150-25-18.5-4 | 150 | 25 | 69.0 | 18.5 | 1450 | 2.5 | 6.5 | 100 | 420 |

16 | 150ZSL150-30-22-4 | 150 | 30 | 69.7 | 22 | 1450 | 2.5 | 7.0 | 100 | 480 |

17 | 150ZSL150-35-30-4 | 150 | 35 | 63.6 | 30 | 1450 | 2.5 | 7.0 | 100 | 660 |

18 | 150ZSL150-40-37-4 | 150 | 40 | 63.6 | 37 | 1450 | 2.5 | 7.0 | 100 | 680 |

19 | 150ZSL150-50-45-4 | 150 | 50 | 67.2 | 45 | 1450 | 2.5 | 7.0 | 100 | 720 |

20 | 150ZSL150-40-37-2 | 150 | 40 | 63.1 | 37 | 2900 | 2.5 | 7.0 | 100 | 480 |

21 | 150ZSL150-50-45-2 | 150 | 50 | 60.6 | 45 | 2900 | 2.5 | 7.0 | 100 | 540 |

22 | 150ZSL150-65-55-2 | 150 | 65 | 64.4 | 55 | 2900 | 2.5 | 7.0 | 100 | 720 |

23 | 150ZSL150-80-75-2 | 150 | 80 | 62.3 | 75 | 2900 | 2.5 | 7.0 | 100 | 880 |

24 | 150ZSL200-11-11-4 | 200 | 11 | 68.1 | 11 | 1450 | 2.5 | 5.5 | 100 | 340 |

25 | 150ZSL200-15-15-4 | 200 | 15 | 68.1 | 15 | 1450 | 2.5 | 6.0 0 | 100 | 370 |

26 | 150ZSL200-18-18.5-4 | 200 | 18 | 66.3 | 18.5 | 1450 | 2.5 | 6.0 | 100 | 420 |

27 | 150ZSL200-22-22-4 | 200 | 22 | 68.1 | 22 | 1450 | 2.5 | 6.5 | 100 | 480 |

28 | 150ZSL200-27-30-4 | 200 | 27 | 65.4 | 30 | 1450 | 2.5 | 7.0 | 100 | 660 |

29 | 150ZSL200-32-37-4 | 200 | 32 | 62.8 | 37 | 1450 | 2.5 | 7.0 | 100 | 680 |

30 | 150ZSL200-40-45-4 | 200 | 40 | 63.7 | 45 | 1450 | 2.5 | 7.0 | 100 | 720 |

31 | 150ZSL200-50-55-4 | 200 | 50 | 65.2 | 45 | 1450 | 2.5 | 7.0 | 100 | 860 |

32 | 150ZSL200-40-45-2 | 200 | 40 | 64.6 | 45 | 2900 | 2.5 | 7.0 | 100 | 540 |

33 | 150ZSL200-50-55-2 | 200 | 50 | 66.1 | 55 | 2900 | 2.5 | 7.0 | 100 | 720 |

34 | 150ZSL200-65-75-2 | 200 | 65 | 63.0 | 75 | 2900 | 2.5 | 7.0 | 100 | 880 |

35 | 150ZSL200-80-90-2 | 200 | 80 | 64.6 | 90 | 2900 | 2.5 | 7.0 | 100 | 950 |

36 | 150ZSL250-50-55-4 | 250 | 50 | 69.7 | 55 | 1450 | 2.5 | 7.0 | 100 | 860 |

37 | 200ZSL250-12-15-6 | 250 | 12 | 68.1 | 15 | 960 | 3.0 | 5.5 | 120 | 480 |

38 | 200ZSL250-15-18-6 | 250 | 15 | 69.0 | 18 | 960 | 3.0 | 6.0 | 120 | 520 |

39 | 200ZSL250-20-22-4 | 250 | 20 | 72.9 | 22 | 1450 | 3.0 | 6.0 0 | 120 | 620 |

40 | 200ZSL250-25-30-4 | 250 | 25 | 66.8 | 30 | 1450 | 3.0 | 6.0 | 120 | 710 |

41 | 200ZSL250-30-37-4 | 250 | 30 | 69.3 | 32 | 1450 | 3.0 | 6.5 | 120 | 820 |

42 | 200ZSL250-40-45-4 | 250 | 40 | 71.2 | 45 | 1450 | 3.0 | 6.5 | 120 | 850 |

43 | 200ZSL250-45-55-4 | 250 | 45 | 69.7 | 55 | 1450 | 3.0 | 7.0 | 120 | 920 |

44 | 200ZSL250-55-75-4 | 250 | 55 | 62.4 | 75 | 1450 | 3.0 | 7.0 | 120 | 980 |

45 | 200ZSL250-65-90-4 | 250 | 65 | 65.6 | 90 | 1450 | 3.0 | 7.0 | 120 | 1030 |

46 | 200ZSL300-10-15-6 | 300 | 10 | 72.7 | 15 | 960 | 3.0 | 5.5 | 120 | 480 |

47 | 200ZSL300-12-18.5-6 | 300 | 12 | 70.7 | 18.5 | 960 | 3.0 | 6.0 | 120 | 520 |

48 | 200ZSL300-15-22-4 | 300 | 15 | 74.3 | 22 | 1450 | 3.0 | 6.0 | 120 | 620 |

49 | 200ZSL300-20-30-4 | 300 | 20 | 72.7 | 30 | 1450 | 3.0 | 6.5 | 120 | 710 |

50 | 200ZSL300-25-37-4 | 300 | 25 | 73.6 | 37 | 1450 | 3.0 | 6.5 | 120 | 820 |

51 | 200ZSL300-30-45-4 | 300 | 30 | 72.7 | 45 | 1450 | 3.0 | 6.5 | 120 | 850 |

52 | 200ZSL300-40-55-4 | 300 | 40 | 74.3 | 55 | 1450 | 3.0 | 7.0 | 120 | 920 |

53 | 200ZSL300-50-75-4 | 300 | 50 | 68.1 | 75 | 1450 | 3.0 | 7.0 | 120 | 980 |

54 | 200ZSL300-55-75-4 | 300 | 55 | 74.9 | 75 | 1450 | 3.0 | 7.0 | 120 | 980 |

55 | 200ZSL300-60-90-4 | 300 | 60 | 68.1 | 90 | 1450 | 3.0 | 7.0 | 120 | 1030 |

56 | 200ZSL350-8-15-6 | 350 | 8 | 63.6 | 15 | 960 | 3.0 | 5.0 | 120 | 580 |

57 | 200ZSL350-11-18.5-6 | 350 | 11 | 70.9 | 18.5 | 960 | 3.0 | 5.5 | 120 | 620 |

58 | 200ZSL350-13-22-4 | 350 | 13 | 70.4 | 22 | 1450 | 3.0 | 5.5 | 120 | 620 |

59 | 200ZSL350-17-30-4 | 350 | 17 | 67.6 | 30 | 1450 | 3.0 | 6.0 | 120 | 710 |

60 | 200ZSL350-22-37-4 | 350 | 22 | 66.7 | 37 | 1450 | 3.0 | 6.5 | 120 | 820 |

61 | 200ZSL350-28-45-4 | 350 | 28 | 69.8 | 45 | 1450 | 3.0 | 6.5 | 120 | 850 |

62 | 200ZSL350-35-55-4 | 350 | 35 | 71.4 | 55 | 1450 | 3.0 | 7.0 | 120 | 920 |

63 | 200ZSL350-42-75-4 | 350 | 42 | 66.8 | 75 | 1450 | 3.0 | 7.0 | 120 | 980 |

64 | 200ZSL350-50-90-4 | 350 | 50 | 66.2 | 90 | 1450 | 3.0 | 7.0 | 120 | 1030 |

65 | 200ZSL350-60-110-4 | 350 | 60 | 65.0 | 110 | 1450 | 3.0 | 7.0 | 120 | 1120 |

66 | 200ZSL400-9-18.5-6 | 400 | 9 | 66.3 | 18.5 | 960 | 3.0 | 5.0 | 120 | 620 |

67 | 200ZSL400-11-22-6 | 400 | 11 | 68.1 | 22 | 960 | 3.0 | 5.5 | 120 | 710 |

68 | 200ZSL400-15-30-4 | 400 | 15 | 68.1 | 30 | 1450 | 3.0 | 6.0 | 120 | 710 |

69 | 200ZSL400-20-37-4 | 400 | 20 | 69.3 | 37 | 1450 | 3.0 | 6.5 | 120 | 820 |

70 | 200ZSL400-25-45-4 | 400 | 25 | 71.2 | 45 | 1450 | 3.0 | 6.5 | 120 | 850 |

71 | 200ZSL400-30-55-4 | 400 | 30 | 69.9 | 55 | 1450 | 3.0 | 7.0 | 120 | 920 |

72 | 200ZSL400-40-75-4 | 400 | 40 | 68.4 | 75 | 1450 | 3.0 | 7.0 | 120 | 980 |

73 | 200ZSL400-48-90-4 | 400 | 48 | 68.4 | 90 | 1450 | 3.0 | 7.0 | 120 | 1030 |

74 | 200ZSL400-55-110-4 | 400 | 55 | 64.1 | 110 | 1450 | 3.0 | 7.0 | 120 | 1120 |

75 | 200ZSL400-65-132-4 | 400 | 65 | 63.1 | 132 | 1450 | 3.0 | 7.0 | 120 | 1160 |

76 | 250ZSL500-12-30-6 | 500 | 12 | 64.1 | 30 | 960 | 4.0 | 5.5 | 150 | 1070 |

77 | 250ZSL500-15-37-4 | 500 | 15 | 65.0 | 37 | 1450 | 4.0 | 6.0 | 150 | 1070 |

78 | 250ZSL500-20-45-4 | 500 | 20 | 71.2 | 45 | 1450 | 4.0 | 6.0 | 150 | 1110 |

79 | 250ZSL500-25-55-4 | 500 | 25 | 72.9 | 55 | 1450 | 4.0 | 6.5 | 150 | 1220 |

80 | 250ZSL500-30-75-4 | 500 | 30 | 64.1 | 75 | 1450 | 4.0 | 6.5 | 150 | 1310 |

81 | 250ZSL500-35-90-4 | 500 | 35 | 62.3 | 90 | 1450 | 4.0 | 6.5 | 150 | 1360 |

82 | 250ZSL500-40-90-4 | 500 | 40 | 71.2 | 90 | 1450 | 4.0 | 6.5 | 150 | 1360 |

83 | 250ZSL600-10-30-6 | 600 | 10 | 64.1 | 30 | 960 | 4.0 | 5.5 | 150 | 1070 |

84 | 250ZSL600-13-37.0-4 | 600 | 13 | 67.6 | 37 | 1450 | 4.0 | 6.0 | 150 | 1070 |

85 | 250ZSL600-16-45.0-4 | 600 | 16 | 68.4 | 45 | 1450 | 4.0 | 6.0 | 150 | 1110 |

86 | 250ZSL600-22-55.0-4 | 600 | 22 | 76.9 | 55 | 1450 | 4.0 | 6.5 | 150 | 1220 |

87 | 250ZSL600-27-75.0-4 | 600 | 27 | 69.2 | 75 | 1450 | 4.0 | 6.5 | 150 | 1310 |

88 | 250ZSL600-32-90.0-4 | 600 | 32 | 68.4 | 90 | 1450 | 4.0 | 6.5 | 150 | 1360 |

89 | 250ZSL600-40-110-4 | 600 | 40 | 69.9 | 110 | 1450 | 4.0 | 6.5 | 150 | 1450 |

90 | 250ZSL600-48-132-4 | 600 | 48 | 69.9 | 132 | 1450 | 4.0 | 6.5 | 150 | 1490 |

91 | 250ZSL600-55-160-4 | 600 | 55 | 66.1 | 160 | 1450 | 4.0 | 6.5 | 150 | 1550 |

92 | 300ZSL800-10-37-6 | 800 | 10 | 69.3 | 37 | 960 | 5.0 | 5.5 | 150 | 1260 |

93 | 300ZSL800-13-45-6 | 800 | 13 | 74.1 | 45 | 960 | 5.0 | 5.5 | 150 | 1350 |

94 | 300ZSL800-16-55-6 | 800 | 16 | 74.6 | 55 | 960 | 5.0 | 5.5 | 150 | 1390 |

95 | 300ZSL800-20-75-4 | 800 | 20 | 68.4 | 75 | 1450 | 5.0 | 6.0 | 150 | 1350 |

96 | 300ZSL800-26-90-4 | 800 | 26 | 74.1 | 90 | 1450 | 5.0 | 6.5 | 150 | 1390 |

97 | 300ZSL800-32-110-4 | 800 | 32 | 74.6 | 110 | 1450 | 5.0 | 6.5 | 150 | 1480 |

98 | 300ZSL800-37-132-4 | 800 | 37 | 71.9 | 132 | 1450 | 5.0 | 6.5 | 150 | 1520 |

99 | 300ZSL800-42-160-4 | 800 | 42 | 67.3 | 160 | 1450 | 5.0 | 6.5 | 150 | 1580 |

100 | 300ZSL1000-8-37-6 | 1000 | 8 | 69.3 | 37 | 960 | 5.0 | 5.5 | 150 | 1260 |

101 | 300ZSL1000-10-45-6 | 1000 | 10 | 71.2 | 45 | 960 | 5.0 | 5.5 | 150 | 1350 |

102 | 300ZSL1000-12-55-6 | 1000 | 12 | 69.9 | 55 | 960 | 5.0 | 6.0 | 150 | 1390 |

103 | 300ZSL1000-16-75-4 | 1000 | 16 | 68.4 | 75 | 1450 | 5.0 | 6.0 | 150 | 1350 |

104 | 300ZSL1000-20-90-4 | 1000 | 20 | 71.2 | 90 | 1450 | 5.0 | 6.5 | 150 | 1390 |

105 | 300ZSL1000-25-110-4 | 1000 | 25 | 72.9 | 110 | 1450 | 5.0 | 6.5 | 150 | 1480 |

106 | 300ZSL1000-30-132-4 | 1000 | 30 | 72.9 | 132 | 1450 | 5.0 | 6.5 | 150 | 1520 |

107 | 300ZSL1000-35-160-4 | 1000 | 35 | 70.1 | 160 | 1450 | 5.0 | 6.5 | 150 | 1580 |

108 | 350ZSL1200-7-37-6 | 1200 | 7 | 72.8 | 37 | 960 | 5.0 | 5.5 | 150 | 1280 |

109 | 350ZSL1200-9-45-6 | 1200 | 9 | 76.9 | 45 | 960 | 5.0 | 5.5 | 150 | 1370 |

110 | 350ZSL1200-11-55-6 | 1200 | 11 | 66.7 | 55 | 960 | 5.0 | 5.5 | 150 | 1420 |

111 | 350ZSL1200-13-75-4 | 1200 | 13 | 72.7 | 75 | 1450 | 5.0 | 6.0 | 150 | 1370 |

112 | 350ZSL1200-17-90-4 | 1200 | 17 | 76.9 | 90 | 1450 | 5.0 | 6.0 | 150 | 1420 |

113 | 350ZSL1200-22-110-4 | 1200 | 22 | 75.8 | 110 | 1450 | 5.0 | 6.5 | 150 | 1510 |

114 | 350ZSL1200-26-132-4 | 1200 | 26 | 72.1 | 132 | 1450 | 5.0 | 6.5 | 150 | 1540 |

115 | 350ZSL1200-30-160-4 | 1200 | 30 | 67.3 | 160 | 1450 | 5.0 | 6.5 | 150 | 1620 |

116 | 350ZSL1200-35-200-4 | 1200 | 35 | 71.5 | 200 | 1450 | 5.0 | 6.5 | 150 | 1710 |

117 | 350ZSL1500-5.5-37-6 | 1500 | 5.5 | 74.8 | 37 | 960 | 5.0 | 6.5 | 150 | 1280 |

118 | 350ZSL1500-7-45-6 | 1500 | 7 | 78.7 | 45 | 960 | 5.0 | 5.5 | 150 | 1370 |

119 | 350ZSL1500-9-55-6 | 1500 | 9 | 70.5 | 55 | 960 | 5.0 | 5.5 | 150 | 1420 |

120 | 350ZSL1500-11-75-4 | 1500 | 11 | 74.8 | 75 | 1450 | 5.0 | 6.0 | 150 | 1370 |

121 | 350ZSL1500-14-90-4 | 1500 | 14 | 74.3 | 90 | 1450 | 5.0 | 6.0 | 150 | 1420 |

122 | 350ZSL1500-17-110-4 | 1500 | 17 | 74.3 | 110 | 1450 | 5.0 | 6.5 | 150 | 1510 |

123 | 350ZSL1500-20-132-4 | 1500 | 20 | 72.9 | 132 | 1450 | 5.0 | 6.5 | 150 | 1540 |

124 | 350ZSL1500-25-160-4 | 1500 | 25 | 75.1 | 160 | 1450 | 5.0 | 6.5 | 150 | 1620 |

125 | 350ZSL1500-30-200-4 | 1500 | 30 | 72.1 | 200 | 1450 | 5.0 | 6.5 | 150 | 1710 |

126 | 350ZSL1500-35-220-4 | 1500 | 35 | 76.5 | 220 | 1450 | 5.0 | 6.5 | 150 | 1820 |

127 | 400ZSL1800-10-90-6 | 1800 | 10 | 64.1 | 90 | 960 | 5.0 | 5.5 | 150 | 1650 |

128 | 400ZSL1800-12-110-6 | 1800 | 12 | 63.0 | 110 | 960 | 5.0 | 6.0 | 150 | 1750 |

129 | 400ZSL1800-15-132-6 | 1800 | 15 | 65.6 | 132 | 960 | 5.0 | 6.5 | 150 | 1860 |

130 | 400ZSL1800-18-160-4 | 1800 | 18 | 64.9 | 160 | 960 | 5.0 | 6.5 | 150 | 1920 |

131 | 400ZSL1800-24-200-6 | 1800 | 24 | 69.2 | 200 | 960 | 5.0 | 6.5 | 150 | 2100 |

132 | 400ZSL1800-26-220-6 | 1800 | 26 | 68.2 | 220 | 960 | 5.0 | 6.5 | 150 | 2200 |

133 | 400ZSL1800-30-250-6 | 1800 | 30 | 69.2 | 250 | 960 | 5.0 | 6.5 | 150 | 2500 |

134 | 400ZSL1800-32-280-4 | 1800 | 32 | 68.2 | 280 | 1450 | 5.0 | 6.5 | 150 | 2400 |

135 | 400ZSL1800-35-315-4 | 1800 | 35 | 64.1 | 315 | 1450 | 5.0 | 6.5 | 150 | 2550 |

136 | 400ZSL2000-9-90-6 | 2000 | 9 | 64.1 | 90 | 960 | 5.0 | 5.5 | 150 | 1650 |

137 | 400ZSL2000-11-110-6 | 2000 | 11 | 64.1 | 110 | 960 | 5.0 | 6.0 | 150 | 1750 |

138 | 400ZSL2000-14-132-6 | 2000 | 14 | 68 | 132 | 960 | 5.0 | 6.0 | 150 | 1860 |

139 | 400ZSL2000-17-160-6 | 2000 | 17 | 68.1 | 160 | 960 | 5.0 | 6.5 | 150 | 1920 |

140 | 400ZSL2000-22-200-6 | 2000 | 22 | 70.5 | 200 | 960 | 5.0 | 6.5 | 150 | 2100 |

141 | 400ZSL2000-24-220-6 | 2000 | 24 | 69.9 | 220 | 960 | 5.0 | 6.5 | 150 | 2200 |

142 | 400ZSL2000-28-250-6 | 2000 | 28 | 71.8 | 250 | 960 | 5.0 | 6.5 | 150 | 2500 |

143 | 400ZSL2000-30-280-4 | 2000 | 30 | 71.2 | 280 | 1450 | 5.0 | 6.5 | 150 | 2400 |

144 | 400ZSL2000-32-315-4 | 2000 | 32 | 65.1 | 315 | 1450 | 5.0 | 6.5 | 150 | 2550 |

145 | 500ZSL2200-8-90-6 | 2200 | 8 | 62.7 | 90 | 960 | 5.0 | 5.5 | 150 | 1680 |

146 | 500ZSL2200-10-110-6 | 2200 | 10 | 64.1 | 110 | 960 | 5.0 | 5.5 | 150 | 1780 |

147 | 500ZSL2200-12-132-6 | 2200 | 12 | 64.1 | 132 | 960 | 5.0 | 6.0 | 150 | 1880 |

148 | 500ZSL2200-15-160-6 | 2200 | 15 | 66.1 | 160 | 960 | 5.0 | 6.5 | 150 | 1950 |

149 | 500ZSL2200-20-200-6 | 2200 | 20 | 70.5 | 200 | 960 | 5.0 | 6.5 | 150 | 2130 |

150 | 500ZSL2200-22-220-6 | 2200 | 22 | 70.5 | 220 | 960 | 5.0 | 6.5 | 150 | 2230 |

151 | 500ZSL2200-25-250-6 | 2200 | 25 | 70.5 | 250 | 960 | 5.0 | 6.5 | 150 | 2530 |

152 | 500ZSL2200-28-280-4 | 2200 | 28 | 70.2 | 280 | 1450 | 5.0 | 6.5 | 150 | 2450 |

153 | 500ZSL2200-30-315-4 | 2200 | 30 | 69.6 | 315 | 1450 | 5.0 | 6.5 | 150 | 2600 |

| |||||||||||||||||

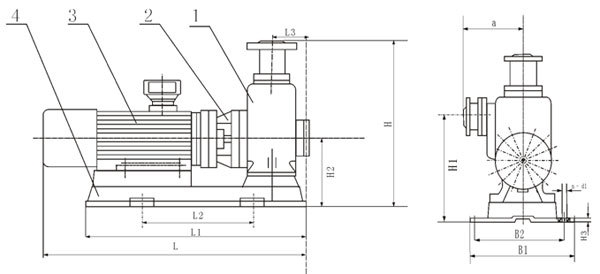

| Serial number | Model number | Mounting dimension | Shock absorber specifications | ||||||||||||||

| ZSL detachable | ZSLL direct connection | L3 | H | H1 | H2 | H3 | a | B1 | B2 | n-d1 | |||||||

| L | L1 | L2 | L | L1 | L2 | ||||||||||||

| 1 | 100ZSL80-10-4-4 | 900 | 820 | 600 | 750 | 670 | 500 | 130 | 900 | 610 | 320 | 20 | 220 | 350 | 300 | 4-φ18 | JGD3 |

| 2 | 100ZSL100-12-5.5-4 | 950 | 850 | 650 | 800 | 700 | 500 | 130 | 900 | 610 | 320 | 20 | 220 | 350 | 300 | 4-φ18 | JGD3 |

| 3 | 100ZSL100-15-7.5-4 | 980 | 850 | 650 | 830 | 700 | 500 | 130 | 900 | 610 | 320 | 20 | 220 | 350 | 300 | 4-φ18 | JGD3 |

| 4 | 100ZSL100-20-11-4 | 1050 | 900 | 700 | 900 | 750 | 550 | 130 | 900 | 610 | 320 | 20 | 220 | 350 | 300 | 4-φ18 | JGD3 |

| 5 | 100ZSL100-25-15-4 | 1100 | 920 | 700 | 950 | 770 | 550 | 130 | 1000 | 710 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD3 |

| 6 | 100ZSL100-30-18.5 | 1120 | 920 | 700 | 970 | 770 | 550 | 130 | 1000 | 710 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD3 |

| 7 | 100ZSL100-40-22-2 | 1120 | 920 | 700 | 970 | 770 | 550 | 130 | 900 | 610 | 320 | 20 | 220 | 400 | 350 | 4-φ18 | JGD3 |

| 8 | 100ZSL100-50-30-2 | 1180 | 1000 | 800 | 980 | 800 | 600 | 130 | 900 | 610 | 320 | 20 | 220 | 400 | 350 | 4-φ18 | JGD3 |

| 9 | 100ZSL100-60-37-2 | 1180 | 1000 | 800 | 980 | 800 | 600 | 130 | 900 | 610 | 320 | 20 | 220 | 400 | 350 | 4-φ18 | JGD3 |

| 10 | 100ZSL100-70-45-2 | 1230 | 1050 | 850 | 1030 | 850 | 650 | 130 | 1020 | 710 | 400 | 20 | 270 | 450 | 400 | 4-φ18 | JGD3 |

| 11 | 100ZSL100-80-45-2 | 1230 | 1050 | 850 | 1030 | 850 | 650 | 130 | 1020 | 710 | 400 | 20 | 270 | 450 | 400 | 4-φ18 | JGD3 |

| 12 | 150ZSL150-10-7.5-4 | 950 | 850 | 650 | 850 | 700 | 500 | 130 | 1000 | 690 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD4 |

| 13 | 150ZSL150-15-11-4 | 1050 | 900 | 700 | 900 | 750 | 550 | 130 | 1000 | 690 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD4 |

| 14 | 150ZSL150-20-15-4 | 1100 | 920 | 700 | 950 | 770 | 550 | 130 | 1000 | 690 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD4 |

| 15 | 150ZSL150-25-18.5 | 1120 | 950 | 750 | 970 | 800 | 600 | 130 | 1000 | 690 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD4 |

| 16 | 150ZSL150-30-22-4 | 1150 | 950 | 750 | 1000 | 800 | 600 | 130 | 1000 | 690 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD4 |

| 17 | 150ZSL150-35-30-4 | 1180 | 1050 | 850 | 980 | 850 | 650 | 155 | 1100 | 805 | 460 | 20 | 270 | 500 | 450 | 4-φ18 | JGD4 |

| 18 | 150ZSL150-40-37-4 | 1200 | 1050 | 850 | 1000 | 850 | 650 | 155 | 1100 | 805 | 460 | 20 | 270 | 500 | 450 | 4-φ18 | JGD4 |

| 19 | 150ZSL150-50-45-4 | 1230 | 1050 | 850 | 1030 | 850 | 650 | 155 | 1100 | 805 | 460 | 20 | 270 | 500 | 450 | 4-φ18 | JGD4 |

| 20 | 150ZSL150-40-37-2 | 1180 | 1000 | 800 | 980 | 800 | 600 | 130 | 1000 | 710 | 400 | 20 | 270 | 450 | 400 | 4-φ18 | JGD4 |

| 21 | 150ZSL150-50-45-2 | 1230 | 1050 | 850 | 1030 | 850 | 600 | 130 | 1000 | 710 | 400 | 20 | 270 | 450 | 400 | 4-φ18 | JGD4 |

| 22 | 150ZSL150-65-55-2 | 1300 | 1150 | 950 | 1100 | 950 | 750 | 130 | 1000 | 710 | 400 | 20 | 270 | 450 | 400 | 4-φ18 | JGD4 |

| 23 | 150ZSL150-80-75-2 | 1380 | 1250 | 1000 | 1180 | 1050 | 800 | 130 | 1000 | 710 | 400 | 20 | 270 | 450 | 400 | 4-φ18 | JGD4 |

| 24 | 150ZSL200-11-11-4 | 1020 | 820 | 620 | 820 | 620 | 420 | 130 | 1000 | 690 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD4 |

| 25 | 150ZSL200-15-15-4 | 1050 | 850 | 650 | 850 | 650 | 450 | 130 | 1000 | 690 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD4 |

| 26 | 150ZSL200-18-18.5 | 1100 | 920 | 720 | 900 | 720 | 520 | 130 | 1000 | 690 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD4 |

| 27 | 150ZSL200-22-22-4 | 1150 | 950 | 750 | 950 | 750 | 550 | 130 | 1000 | 690 | 380 | 20 | 270 | 400 | 350 | 4-φ18 | JGD4 |

| 28 | 150ZSL200-27-30-4 | 1180 | 1000 | 800 | 980 | 800 | 600 | 130 | 1000 | 805 | 460 | 20 | 270 | 400 | 350 | 4-φ18 | JGD4 |

| 29 | 150ZSL200-32-37-4 | 1200 | 1120 | 920 | 1000 | 920 | 720 | 155 | 1100 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 30 | 150ZSL200-40-45-4 | 1230 | 1150 | 950 | 1030 | 950 | 750 | 155 | 1100 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 31 | 150ZSL200-50-55-4 | 1300 | 1200 | 1000 | 1100 | 1000 | 800 | 155 | 1100 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 32 | 150ZSL200-40-45-2 | 1230 | 1050 | 850 | 1030 | 850 | 650 | 130 | 1000 | 710 | 400 | 20 | 270 | 450 | 400 | 4-φ18 | JGD4 |

| 33 | 150ZSL200-50-55-2 | 1300 | 1150 | 950 | 1100 | 950 | 750 | 130 | 1000 | 710 | 400 | 20 | 270 | 450 | 400 | 4-φ18 | JGD4 |

| 34 | 150ZSL200-65-75-2 | 1380 | 1250 | 1050 | 1180 | 1050 | 850 | 130 | 1000 | 710 | 400 | 20 | 270 | 450 | 400 | 4-φ18 | JGD4 |

| 35 | 150ZSL200-80-90-2 | 1450 | 1320 | 1120 | 1250 | 1120 | 920 | 130 | 1000 | 710 | 400 | 20 | 270 | 450 | 400 | 4-φ18 | JGD4 |

| 36 | 150ZSL250-50-55-4 | 1400 | 1200 | 1000 | 1200 | 1000 | 800 | 155 | 1160 | 805 | 460 | 20 | 450 | 550 | 500 | 4-φ18 | JGD4 |

| 37 | 200ZSL250-12-15-6 | 1230 | 1000 | 800 | 1030 | 800 | 600 | 155 | 1140 | 785 | 440 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 38 | 200ZSL250-15-18-6 | 1280 | 1050 | 850 | 1080 | 850 | 650 | 155 | 1140 | 785 | 440 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 39 | 200ZSL250-20-22-4 | 1280 | 1050 | 850 | 1080 | 850 | 650 | 155 | 1140 | 785 | 440 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 40 | 200ZSL250-25-30-4 | 1320 | 1080 | 900 | 1120 | 880 | 700 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 41 | 200ZSL250-30-37-4 | 1340 | 1120 | 900 | 1140 | 920 | 700 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD3 |

| 42 | 200ZSL250-40-45-4 | 1370 | 1150 | 950 | 1170 | 950 | 750 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD3 |

| 43 | 200ZSL250-45-55-4 | 1400 | 1200 | 1000 | 1200 | 1000 | 800 | 155 | 1160 | 805 | 460 | 20 | 450 | 550 | 500 | 4-φ18 | JGD4 |

| 44 | 200ZSL250-55-75-4 | 1460 | 1250 | 1050 | 1260 | 1050 | 850 | 155 | 1220 | 850 | 510 | 20 | 450 | 600 | 550 | 4-φ18 | JGD4 |

| 45 | 200ZSL250-65-90-4 | 1520 | 1300 | 1100 | 1320 | 1100 | 900 | 155 | 1220 | 850 | 510 | 20 | 450 | 600 | 550 | 4-φ18 | JGD4 |

| 46 | 200ZSL300-10-15-6 | 1230 | 1000 | 800 | 1030 | 800 | 600 | 155 | 1140 | 785 | 440 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 47 | 200ZSL300-12-18.5-4 | 1280 | 1050 | 850 | 1080 | 850 | 650 | 155 | 1140 | 785 | 440 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 48 | 200ZSL300-15-22-4 | 1280 | 1050 | 850 | 1080 | 850 | 650 | 155 | 1140 | 785 | 440 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 49 | 200ZSL300-20-30-4 | 1320 | 1080 | 900 | 1120 | 880 | 680 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 50 | 200ZSL300-25-37-4 | 1340 | 1120 | 900 | 1140 | 920 | 700 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 51 | 200ZSL300-30-45-4 | 1370 | 1150 | 950 | 1170 | 950 | 750 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 52 | 200ZSL300-40-55-4 | 1400 | 1200 | 1000 | 1200 | 1000 | 800 | 155 | 1160 | 805 | 460 | 20 | 450 | 550 | 500 | 4-φ18 | JGD4 |

| 53 | 200ZSL300-50-75-4 | 1460 | 1250 | 1050 | 1260 | 1050 | 850 | 155 | 1220 | 850 | 510 | 20 | 450 | 600 | 550 | 4-φ18 | JGD4 |

| 54 | 200ZSL300-55-75-4 | 1460 | 1250 | 1050 | 1260 | 1050 | 850 | 155 | 1220 | 850 | 510 | 20 | 450 | 600 | 550 | 4-φ18 | JGD4 |

| 55 | 200ZSL300-60-90-4 | 1520 | 1300 | 1100 | 1320 | 1100 | 900 | 155 | 1220 | 850 | 510 | 20 | 450 | 600 | 550 | 4-φ18 | JGD4 |

| 56 | 200ZSL350-8-15-6 | 1230 | 1000 | 800 | 1030 | 800 | 600 | 155 | 1140 | 785 | 440 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 57 | 200ZSL350-11-18.5-6 | 1280 | 1050 | 850 | 1080 | 850 | 650 | 155 | 1140 | 785 | 460 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 58 | 200ZSL350-13-22-6 | 1320 | 1080 | 900 | 1120 | 880 | 680 | 155 | 1140 | 785 | 460 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 59 | 200ZSL350-17-30-4 | 1320 | 1080 | 900 | 1120 | 880 | 680 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 60 | 200ZSL350-22-37-4 | 1340 | 1120 | 900 | 1140 | 920 | 700 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 61 | 200ZSL350-28-45-4 | 1370 | 1150 | 950 | 1170 | 950 | 750 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 62 | 200ZSL350-35-55-4 | 1400 | 1200 | 1000 | 1200 | 1000 | 800 | 155 | 1160 | 805 | 460 | 20 | 450 | 550 | 500 | 4-φ18 | JGD4 |

| 63 | 200ZSL350-42-75-4 | 1460 | 1250 | 1050 | 1260 | 1050 | 850 | 155 | 1160 | 805 | 460 | 20 | 450 | 550 | 500 | 4-φ18 | JGD4 |

| 64 | 200ZSL350-50-90-4 | 1520 | 1300 | 1100 | 1320 | 1100 | 900 | 155 | 1220 | 850 | 510 | 20 | 450 | 600 | 550 | 4-φ18 | JGD4 |

| 65 | 200ZSL350-60-110-4 | 1670 | 1400 | 1200 | 1470 | 1200 | 1000 | 155 | 1220 | 850 | 510 | 20 | 450 | 600 | 550 | 4-φ18 | JGD4 |

| 66 | 200ZSL400-9-18.5-6 | 1280 | 1050 | 850 | 1080 | 850 | 650 | 155 | 1140 | 785 | 440 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 67 | 200ZSL400-11-22-6 | 1320 | 1080 | 900 | 1120 | 880 | 680 | 155 | 1140 | 785 | 440 | 20 | 450 | 450 | 400 | 4-φ18 | JGD4 |

| 68 | 200ZSL400-15-30-4 | 1320 | 1080 | 900 | 1120 | 880 | 680 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 69 | 200ZSL400-20-37-4 | 1340 | 1120 | 900 | 1140 | 920 | 700 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 70 | 200ZSL400-25-45-4 | 1370 | 1150 | 950 | 1170 | 950 | 750 | 155 | 1160 | 805 | 460 | 20 | 450 | 500 | 450 | 4-φ18 | JGD4 |

| 71 | 200ZSL400-30-55-4 | 1400 | 1200 | 1000 | 1200 | 1000 | 800 | 155 | 1160 | 805 | 460 | 20 | 450 | 550 | 500 | 4-φ18 | JGD4 |

| 72 | 200ZSL400-40-75-4 | 1460 | 1250 | 1050 | 1260 | 1050 | 850 | 155 | 1160 | 805 | 460 | 20 | 450 | 550 | 500 | 4-φ18 | JGD4 |

| 73 | 200ZSL400-48-90-4 | 1520 | 1300 | 1100 | 1320 | 1100 | 900 | 155 | 1220 | 850 | 510 | 20 | 450 | 600 | 550 | 4-φ18 | JGD4 |

| 74 | 200ZSL400-55-110-4 | 1670 | 1400 | 1200 | 1470 | 1200 | 1000 | 155 | 1220 | 850 | 510 | 20 | 450 | 600 | 550 | 4-φ18 | JGD4 |

| 75 | 200ZSL400-65-132-4 | 1670 | 1400 | 1200 | 1470 | 1200 | 1000 | 155 | 1220 | 850 | 510 | 20 | 450 | 600 | 550 | 4-φ18 | JGD4 |

| 76 | 250ZSL500-12-30-6 | 1520 | 1270 | 800 | 1320 | 1070 | 600 | 230 | 1350 | 950 | 500 | 20 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 77 | 250ZSL500-15-37-4 | 1520 | 1270 | 800 | 1320 | 1070 | 600 | 230 | 1350 | 950 | 500 | 20 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 78 | 250ZSL500-20-45-4 | 1550 | 1300 | 850 | 1350 | 1100 | 650 | 230 | 1350 | 950 | 500 | 20 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 79 | 250ZSL500-25-55-4 | 1600 | 1350 | 850 | 1350 | 1150 | 700 | 230 | 1350 | 950 | 500 | 20 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 80 | 250ZSL500-30-75-4 | 1680 | 1400 | 950 | 1480 | 1200 | 750 | 230 | 1350 | 950 | 500 | 20 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 81 | 250ZSL500-35-90-4 | 1730 | 1430 | 950 | 1530 | 1230 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 82 | 250ZSL500-40-90-4 | 1730 | 1430 | 950 | 1530 | 1230 | 750 | 230 | 1420 | 1020 | 560 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 83 | 250ZSL600-10-30-6 | 1520 | 1270 | 800 | 1320 | 1070 | 600 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 84 | 250ZSL600-13-37.0-4 | 1520 | 1270 | 800 | 1320 | 1070 | 600 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 85 | 250ZSL600-16-45.0-4 | 1550 | 1300 | 850 | 1350 | 1100 | 650 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 86 | 250ZSL600-22-55.0-4 | 1600 | 1350 | 900 | 1400 | 1150 | 700 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 87 | 250ZSL600-27-75.0-4 | 1680 | 1400 | 950 | 1480 | 1200 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 88 | 250ZSL600-32-90.0-4 | 17300 | 1430 | 950 | 1530 | 1250 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 89 | 250ZSL600-40-110-4 | 1880 | 1500 | 1050 | 1680 | 1300 | 850 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 90 | 250ZSL600-48-132-4 | 1880 | 1500 | 1050 | 1680 | 1300 | 850 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 91 | 250ZSL600-55-160-4 | 19500 | 1550 | 1100 | 1750 | 1350 | 900 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 92 | 300ZSL800-10-37-6 | 1600 | 1350 | 900 | 1400 | 1150 | 700 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 93 | 300ZSL800-13-45-6 | 1680 | 1400 | 950 | 1480 | 1200 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 94 | 300ZSL800-16-55-6 | 1730 | 1430 | 950 | 1530 | 1230 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 95 | 300ZSL800-20-75-4 | 1680 | 1400 | 950 | 1480 | 1200 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 96 | 300ZSL800-26-90-4 | 1730 | 1430 | 950 | 1530 | 1230 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 97 | 300ZSL800-32-110-4 | 1880 | 1500 | 1050 | 1680 | 1300 | 850 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 98 | 300ZSL800-37-132-4 | 1880 | 1500 | 1050 | 1680 | 1300 | 850 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 99 | 300ZSL800-42-160-4 | 19500 | 1550 | 1100 | 1750 | 1350 | 900 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 100 | 300ZSL1000-8-37-6 | 1600 | 1350 | 900 | 1400 | 1150 | 700 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 101 | 300ZSL1000-10-45-6 | 1680 | 1400 | 950 | 1480 | 1200 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 102 | 300ZSL1000-12-55-6 | 17300 | 1430 | 950 | 1530 | 1250 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 103 | 300ZSL1000-16-75-4 | 1680 | 1400 | 950 | 1480 | 1200 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 104 | 300ZSL1000-20-90-4 | 17300 | 1430 | 950 | 1530 | 1250 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 105 | 300ZSL1000-25-110-4 | 1880 | 1500 | 1050 | 1680 | 1300 | 850 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 106 | 300ZSL1000-30-132-4 | 1880 | 1500 | 1050 | 1680 | 1300 | 850 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 107 | 300ZSL1000-35-160-4 | 19500 | 1550 | 1100 | 1750 | 1350 | 900 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 108 | 350ZSL1200-7-37-6 | 1600 | 1350 | 900 | 1400 | 1150 | 700 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 109 | 350ZSL1200-9-45-6 | 1680 | 1400 | 950 | 1480 | 1200 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 110 | 350ZSL1200-11-55-6 | 17300 | 1430 | 950 | 1530 | 1250 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 111 | 350ZSL1200-13-75-4 | 1680 | 1400 | 950 | 1480 | 1200 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 112 | 350ZSL1200-17-90-4 | 17300 | 1430 | 950 | 1530 | 1250 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 113 | 350ZSL1200-22-110-4 | 1880 | 1500 | 1050 | 1680 | 1300 | 850 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 114 | 350ZSL1200-26-132-4 | 1880 | 1500 | 1050 | 1680 | 1300 | 850 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 115 | 350ZSL1200-30-160-4 | 19500 | 1550 | 1100 | 1750 | 1350 | 900 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 116 | 350ZSL1200-35-200-4 | 2020 | 1600 | 1150 | 1820 | 1400 | 950 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 117 | 350ZSL1500-5.5-37-6 | 1600 | 1350 | 900 | 1400 | 1150 | 700 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 118 | 350ZSL1500-7-45-6 | 1680 | 1400 | 950 | 1480 | 1200 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 119 | 350ZSL1500-9-55-6 | 17300 | 1430 | 950 | 1530 | 1250 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 120 | 350ZSL1500-11-75-4 | 1680 | 1400 | 950 | 1480 | 1200 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 121 | 350ZSL1500-14-90-4 | 17300 | 1430 | 950 | 1530 | 1250 | 750 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 122 | 350ZSL1500-17-110-4 | 1880 | 1500 | 1050 | 1680 | 1300 | 850 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 123 | 350ZSL1500-20-132-4 | 1880 | 1500 | 1050 | 1680 | 1300 | 850 | 230 | 1350 | 950 | 500 | 30 | 600 | 600 | 550 | 4-φ18 | JGD4 |

| 124 | 350ZSL1500-25-160-4 | 19500 | 1550 | 1100 | 1750 | 1350 | 900 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 125 | 350ZSL1500-30-200-4 | 2020 | 1600 | 1150 | 1820 | 1400 | 950 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

| 126 | 350ZSL1500-35-220-4 | 2100 | 1650 | 1200 | 1900 | 1450 | 1000 | 230 | 1420 | 1020 | 560 | 30 | 660 | 650 | 600 | 4-φ18 | JGD4 |

Installation instructions

1. Before installation, check whether the fasteners of the unit are loose, and whether there is foreign matter blocked in the flow channel of the pump body, so as to avoid damage to the impeller and pump body during operation.

2, the weight of the pipeline should not be added to the pump during installation, and there should be respective supporting bodies to avoid affecting the operation performance and service life of the pump when it is deformed.

3, such as the pump is used to transport hot water or other high temperature liquid, in order not to make the pump withstand the thermal deformation of the pipeline, the pump can not fix the foot bolt, when the pipeline system in the heat expansion and contraction, the pump and the pipeline move at the same time.

4, in order to facilitate the maintenance and use, the inlet and outlet pipe of the pump should be installed with a regulating valve and a pressure gauge near the inlet and outlet of the pump to allow the pump to operate within the rated range to ensure the normal operation and service life of the pump.

Start, run and stop

(1) Starting and running:

1. If the wind blade of the motor is stuck or abnormal sound, it can be started normally.

2, open the upper water valve, add liquid storage water not less than two-thirds of the volume of the pump body, close the valve. There is no need to pour water to start the machine later.

3, close the pipe outlet valve to reduce the starting current. Connect the power supply to try to turn, from the motor end, for clockwise steering. (No reversal)

4. Gradually adjust the opening of the outlet valve to make the pump work within the rated performance range as far as possible.

5, during the operation of the pump, if any abnormality is found, it should be stopped immediately to check and exclude.

6. Check whether the current value and temperature rise of the motor meet the requirements.

(2) Parking

1, close the pump outlet pipeline valve.

2, cut off the power supply, stop the motor running.

3. Close the inlet valve.

4. When the pump is disabled for a long time, the storage liquid should be drained, and the storage liquid should be drained when the weather is cold and the freezing point is used, so as not to freeze and crack the pump body.

Common fault analysis and troubleshooting methods

| Fault phenomenon | Cause analysis | Troubleshooting |

| Can't pump out water | 1. No liquid storage is added in the pump body or insufficient liquid storage is | 1. Add enough |

| 2. Air leakage in the suction pipe | 2. Eliminate air leakage in pipelines | |

| 3. The voltage is too low | 3. Adjust the voltage | |

| 4. The suction range is too high or the suction pipe is too long | 4. Reduce suction range or shorten the pipe circuit | |

| 5. The motor running direction is incorrect | 5. Adjust the motor direction | |

| 6. Lack of phase | 6. Check the line for repair | |

| 7. The pumping medium has a high density or a high viscosity | 7. Use water to dilute the concentration or reduce viscosity | |

| 8. The head is too high | 8. Change the pump or lower the head | |

| Insufficient pumping water | 1. Due to improper use, the impeller flow channel or suction pipe is blocked | 1. Fire blockage |

| 2. Severe wear of the impeller | 2. Replace the impeller | |

| 3. Sealing ring damaged (or ring) | 3. Replace | |

| Pump noise and excessive vibration | 1. Unstable feet | 1. Strengthen |

| 2. Severe wear of bearings | 2. Replace bearings | |

| Motor heating | 1. The traffic is too large and overloaded | 1. Close the small outlet valve |

| 2. Touch | 2. Check and eliminate | |

| 3. Bearings damaged | 3. Replace | |

| 4. Insufficient voltage | 4. Stable pressure | |

| 5. High media density | 5. Dilute the medium or change the impeller | |

| Pump leak | 1. Loose coupling bolts | 1. Tighten |

| 2. Wear of seals | 2. Replace | |

| 3. There are sand holes or cracks in the pump body | 3. Welding repair or replacement | |

| 4. The sealing surface is uneven | 4. Trim |

Home

Home Tel

Tel Product

Product