ZX/ZW self-priming pump manufacturers

Number of views:21

QR code:

Add time:2025-04-10

Brief:

Summarize

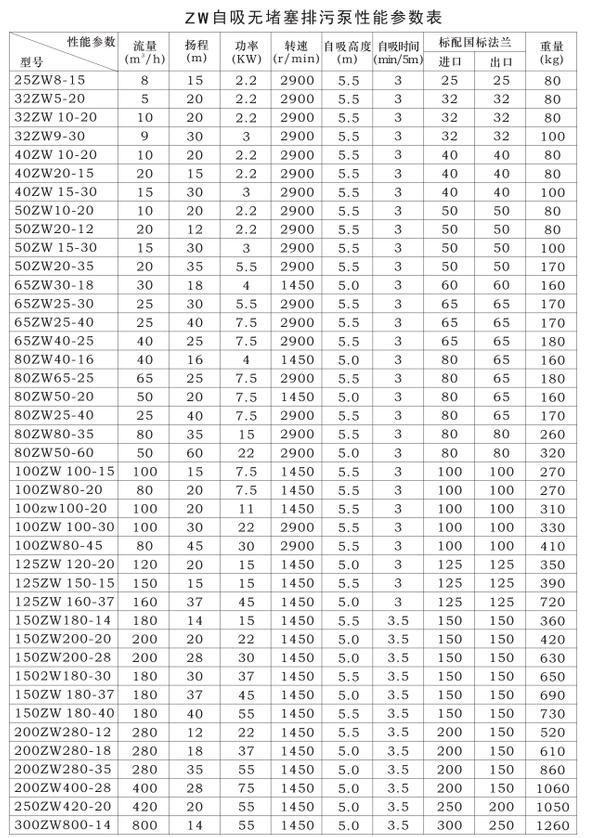

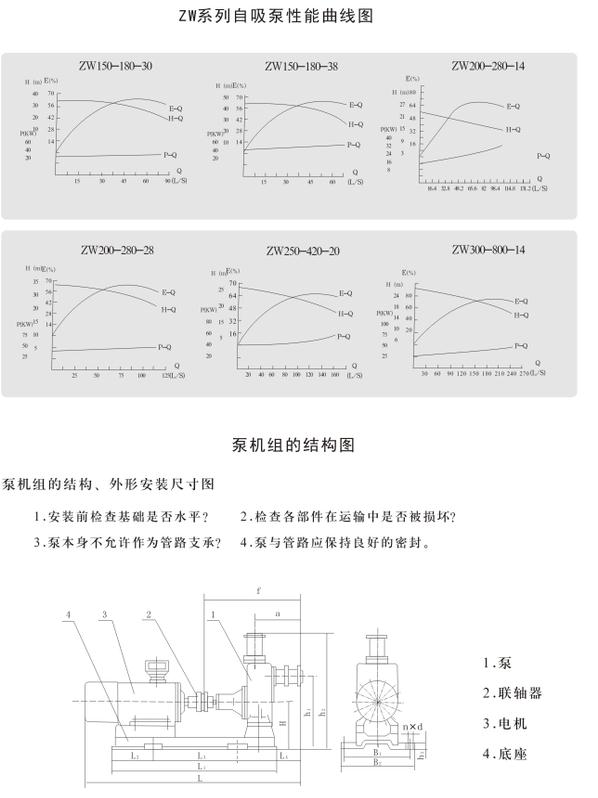

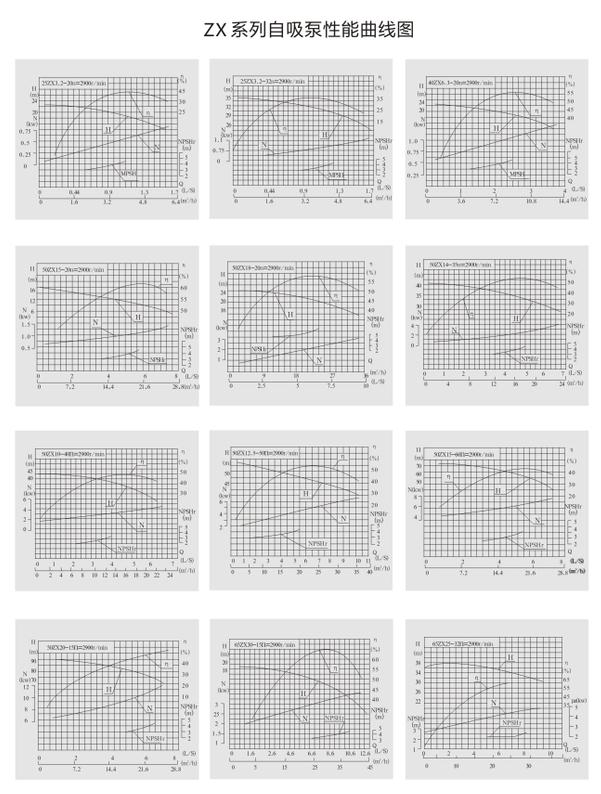

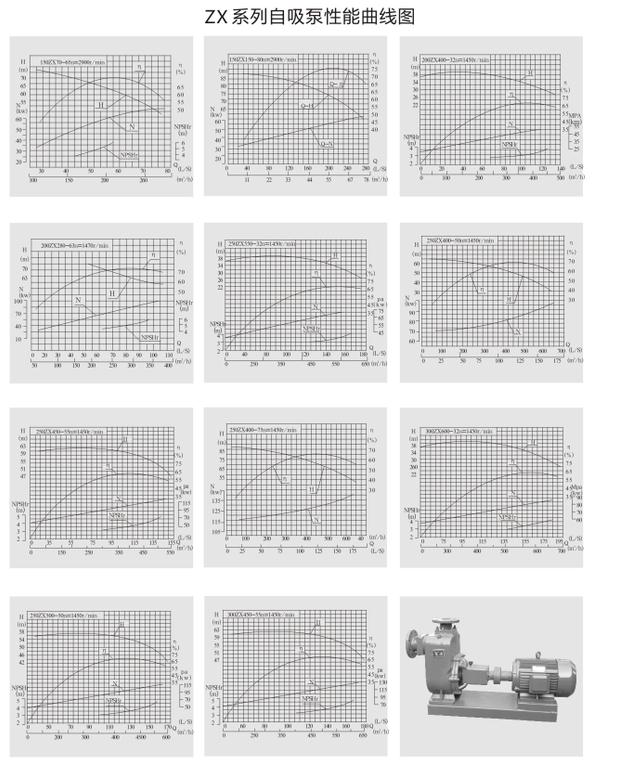

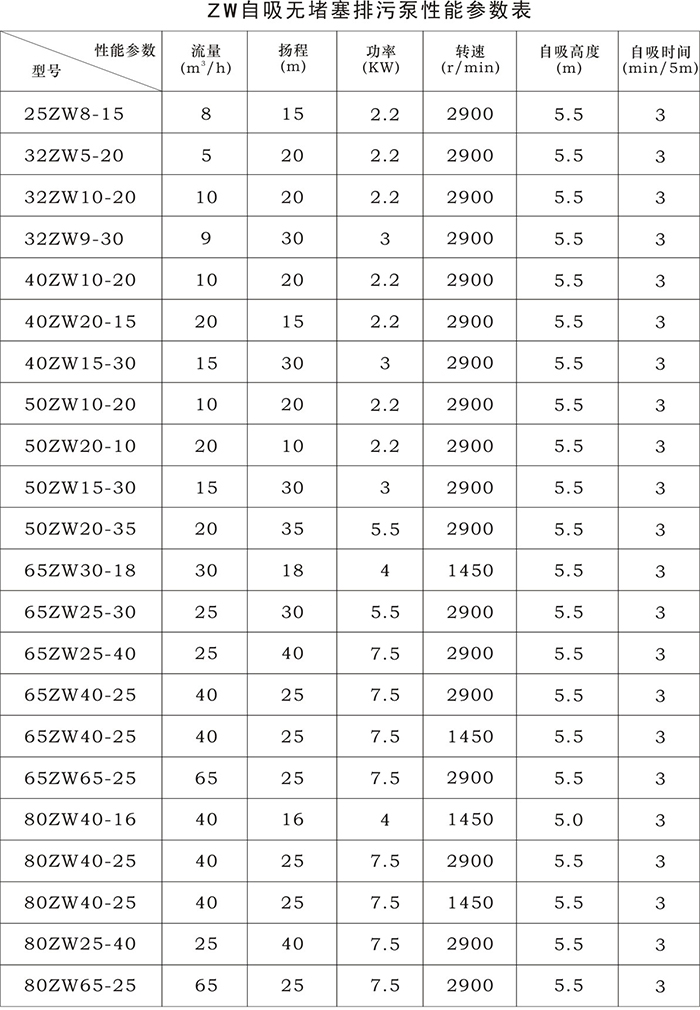

ZX and ZW series self-priming pumps produced by our factory are energy-saving pump products developed after absorption, digestion and improvement according to relevant technical data at home and abroad. The pump is a self-priming centrifugal pump, which has the advantages of compact structure, convenient operation, stable operation, easy maintenance, high efficiency, long life, and strong self-priming ability. There is no need to install the bottom valve in the pipeline, and only need to store quantitative primer in the pump body before work; w pump set self-priming and non-clogging sewage in one, adopt axial return external mixing, and through the unique design of pump body, impeller flow channel, can be like the general self-priming clean pump does not need to install the bottom valve and irrigation, but also can suck and discharge containing large particles of solid long fiber impurity liquid, so simplify the pipeline system, but also improve the working conditions.

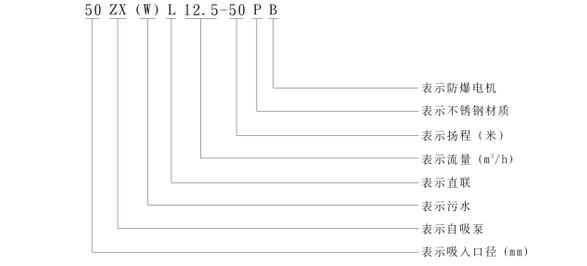

Model meaning example

Application range of pump

1. suitable for city, construction, fire, chemical, pharmaceutical, printing and dyeing, brewing, electricity, electroplating, paper making, industrial and mining washing, equipment cooling, etc.

2. equipped with rocker nozzle, but also can wash water into the air, scattered into small raindrops for spray, is a good machine for farms, nurseries, orchards, tea gardens.

3. suitable for clean water, sea water, and chemical medium liquid with acid and alkalinity and slurry with general paste (Medium viscosity <100 cm per cent, solid content up to 30%).

4. can be used with any type, specifications of the filter press, the slurry is sent to the filter press for the ideal supporting pump.

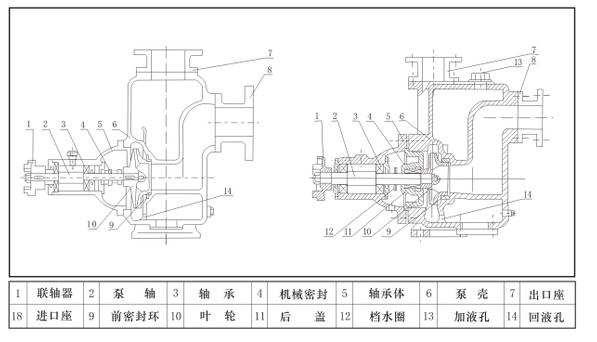

Working principle and structure description

The pump adopts the pump body structure of axial return liquid. The pump body is composed of suction chamber, liquid storage chamber, vortex chamber, liquid return hole, gas-liquid separation chamber, etc. After the pump starts normally, the liquid stored in the impeller pulp suction chamber and the air in the suction pipe are inhaled together, and can be completely mixed in the impeller. Under the action of centrifugal force, the liquid carries the gas to the outer edge of the vortex, and forms a white foam belt with a certain thickness and a high-speed rotating liquid ring on the outer edge of the impeller. The gas-liquid mixture enters the gas-liquid separation chamber through the diffusion tube. At this time, due to the sudden decrease in the flow rate, the lighter gas is separated from the gas-liquid mixture, and the gas continues to rise and discharge through the pump body. The degassed liquid returns to the liquid storage chamber, and enters the impeller again through the return hole, and mixes with the gas inhaled from the suction pipe inside the impeller again. Under the action of the high-speed rotating impeller, the liquid flows to the outside of the impeller to train.... As this process goes on again and again, the air in the suction line is continuously reduced until the gas is sucked out, the self-priming process is completed, and the pump is put into normal operation.

A cooling chamber is also provided at the bottom of the bearing body of some pumps. When the bearing heat causes the bearing temperature to exceed 70℃, the coolant can be injected into the cooling chamber through any coolant pipe joint. The sealing mechanism inside the pump to prevent the leakage of liquid from the high pressure area to the low pressure area is the front and rear sealing ring, the front sealing ring is installed on the pump body, and the rear sealing ring is installed on the bearing body, when the pump is worn to a certain extent after long-term operation of the sealing ring, and affects the efficiency and self-priming performance of the pump, it should be replaced.

Name of the main structural part

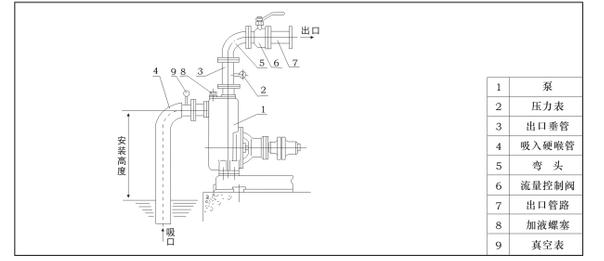

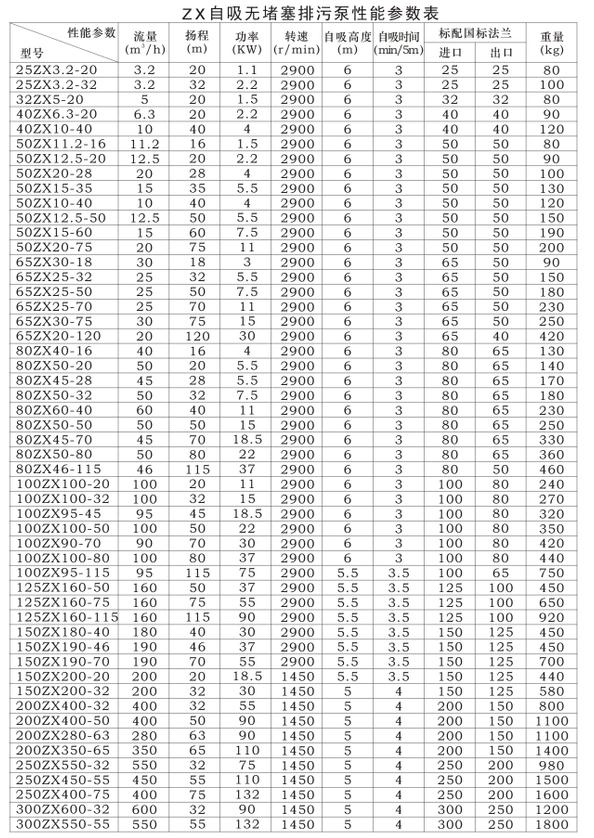

Pump installation precautions

1. When the pump and the motor are directly connected, attention should be paid to the coaxiality of the pump shaft and the motor output; The accuracy of the pump installation has a great impact on the smoothness and service life of the pump, so it must be carefully installed and corrected.

2. the pump coupling must be fastened with nuts, and lock the nuts, beware of loose nuts, otherwise it is easy to cause the impeller to move, resulting in mechanical failure.

3. in order to maintain a certain amount of storage liquid in the pump body, in order to achieve better self-priming capacity and prevent dry friction of mechanical seal, it is necessary to make the pump inlet higher than the center line of the pump shaft.

4. the installation of suction pipe should pay attention to :A. The installation height of the suction inlet can not be more than 5 meters, when conditions permit, the installation height of the suction inlet should be as low as possible below the water storage plane of the pool, and try to shorten the length of the suction pipe, less elbow, which is conducive to shorten the self-priming time and improve the self-priming function. B. The valves and flanges in the suction pipe should be strictly prevented from leaking air or liquid, that is, the suction pipe is not allowed to leak air. C. The pump should be prevented from inhaling solids and other debris, for which a filter should be set up on the suction pipe. The effective flow area of the filter should be 2-3 times the cross-section of the suction tube, and the filter should be checked regularly. D. The suction pipe and the discharge pipe should have their own supports, and the pump body itself is not allowed to bear the load of the pipeline.

5. the outlet vertical pipe installation is not less than 0.5 meters high to the outlet flange, the outlet flow control valve must be installed.

6. when the pump is installed, the electrostatic grounding resistance of the pump and pipeline should be used to meet its specified requirements.

7. the installation should be strictly checked in the pump shell and pipeline for stones, iron sand and other debris.

8. Correct the installation clearance and coaxiality of the pump coupling and electric motor coupling, and the allowable deviation of the non-coaxiality is 0.1 mm. The height difference between the pump shaft and the motor shaft can be adjusted by placing copper or iron on the foot.

9. in the actual operation of the unit 3-4 hours after the check, if there is no adverse phenomenon, it is considered that the installation has been properly, in the test run should check the temperature of the bearing, bearing body temperature should not be more than 70℃.

10. where the pump bearing body is equipped with a cooling chamber device, it is necessary to connect circulating water to cool the bearing chamber. The joint size is 1/2 pipe thread or 3/8 pipe thread.

11. If a check valve is installed on the outlet pipe of the pump and the pump cannot discharge gas smoothly during the self-priming process, the exhaust water pipe and valve should be connected at the outlet of the pump.

Home

Home Tel

Tel Product

Product